In this issue, I will take you through 20 points on what thermal insulation strips are and how to choose and use them for windows and doors.

Do all aluminium doors and windows have thermal strips?

No, they are not.

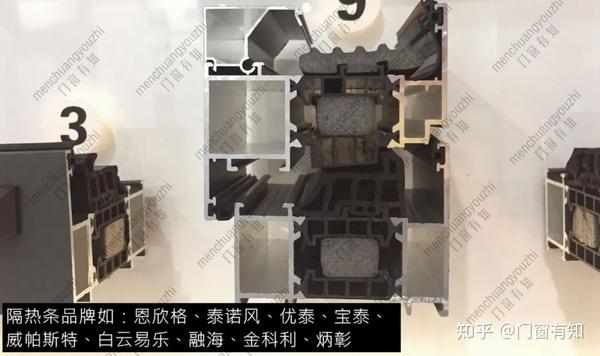

Aluminium windows and doors are divided into two generations, the main materials are pure aluminium profiles and insulated aluminium profiles.

The former, such as the aluminium sliding windows that are still used in many old communities, do not have thermal insulation strips.

The latter is often referred to as ‘broken aluminium’, which is one of the mainstream choices for new windows and doors, and has thermal insulation strips.

What is the function of the thermal insulation strips?

It is designed to improve the thermal insulation of window and door profiles. The reason for this is that the thermal conductivity of the pure aluminium profiles of the previous generation of aluminium windows and doors was too high, which made it very easy to transfer the temperature difference between inside and outside, making the thermal insulation of the windows and doors poor. (The thermal conductivity of aluminium is about 160 W/mK and the thermal conductivity of ordinary PA66GF25 is about 0.3 W/mK) So a solution was devised to improve this by rejoining the two ends of the profile with a cut of material with a lower thermal conductivity to become a window and door profile material again, giving the window and door profile a hot and cold bridge. When outdoor/internal heat is again transferred through the aluminium, the thermal insulation profile (i.e. thermal strip) acts as a cold bridge, blocking and slowing down the heat transfer between the two profiles, thus improving the thermal insulation effect of the window and door product.

Are all insulation strips made of the same material?

No, they are not. The two main types of insulation available on the market are polyvinyl chloride (PVC) and polyamide 66 (PA 66, also known as nylon insulation). There is a wide range of different materials available on the market, from the early days (more than ten years ago) when PVC insulation was popular in China. In the early days (more than ten years ago) PVC insulation was popular in China, but as the market was tested and technical research was carried out, polyamide 66 with 25 % glass fibre (PA66GF25) is now the mainstream material for insulation strips.

Why PA66GF25?

The tensile strength of PA66GF25 insulation strips can generally reach more than 80 MPa, while PVC can only reach 35 – 48 MPa. The coefficient of linear expansion of aluminium profiles is 2.35 x 10 (-5, upper right corner of 10, same below), PA66GF25 3.0 x 10-5, PVC 8 x 10-5. The coefficient of linear expansion of aluminium profiles is 2.35 x 10 (-5, top right corner of 10), PA66GF25 is 3.0 x 10-5 and PVC is 8 x 10-5. The closer the coefficient of linear expansion is to the two materials, the more they can maintain synchronous expansion and contraction when the ambient temperature changes, thus ensuring the structural integrity of the thermal insulation strips and aluminium profiles. PVC is not resistant to high and low temperatures, and the material will be deformed, brittle and prone to ageing, which will lead to safety hazards.

Am I prone to buying poor-quality insulation strips if I’m not careful?

From a personal and subjective point of view, there is no need to worry too much about the type of material: nylon insulation strips are the main choice for windows and doors; PVC strips are still available in a few markets, but they are rare and most likely to be found in low-cost products (below market price). It is prudent to ask for the brand of the strip or for proof of supply/cooperation when shopping. There are relatively more problems with the quality of insulation: consumers are more likely to buy poor-quality nylon insulation than PVC insulation. Poor quality nylon insulation strips, such as those with less glass fibre, those adulterated with mineral powder, or those using recycled or waste materials for secondary processing, can directly affect the performance and life of the strip. To deal with this problem, either buy relatively well-known branded windows or choose windows and doors with branded insulation strips.

Can I buy fake heat insulation strips?

Possibly, there are two scenarios here.

One is that it does not match the publicity of the merchant, a common situation such as publicity when the merchant said that the insulation strip brand is a certain brand, later you find that the use of other brands, to pursue when the merchant said that a certain brand is additional, to spend money.

The second is the sale of counterfeit, of which the case of impersonating TECHNOFORM is very common.

PA66GF25 is more advanced than PA66?

When recommending their own window and door products, some merchants will say “we use PA66GF25, which is 25% more glass fibre than PA66 nylon insulation, so it is more advanced/expensive/good”. GF25 does mean that there is 25% more glass fibre in the insulation, and the glass fibre is indeed used to make the insulation stronger. However, most of the commercially available insulation strips contain 25 % glass fibre, and what we usually call nylon insulation strips or PA 66 nylon insulation strips is just short-hand, not that they do not have glass fibre added.

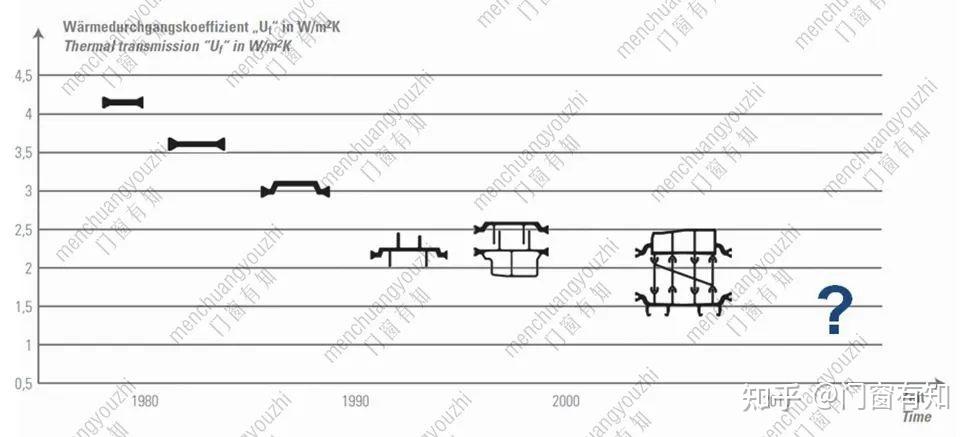

Is there a difference in the processing of insulation strips?

There are differences in the processing end of the thermal insulation strips for different door and window production products. From the processing process, there are two kinds of heat insulation strips, namely, strip-through heat insulation strips and poured heat insulation strips, because of the process, cost, performance and other factors, now the market is basically based on strip-through bridge profiles. From the perspective of the pierced profile, some window and door manufacturers will buy the profile directly from the profile factory, i.e. already pierced with strips (mostly small and medium-sized factories). Some window and door manufacturers will purchase their own heat insulation strips and corresponding aluminium profiles and assemble them (mostly in medium and large factories).

Is it more reliable for a factory to thread its own insulation strips than for a factory to buy a breakaway profile?

It is not. Whether or not you thread your own strips is actually a matter for the factory to consider for its own costs. If my factory has a large volume, I can save on the stock of profiles by wearing the insulation strips myself, and the overall purchase cost is lower.

If a small factory buys from a well-known aluminium material, the quality of the broken bridge profile is guaranteed. Some factories that are not standardised, or have low technical maturity, wear insulation strips of poor quality, but the performance of the bridge profile is not up to standard.

How do I know the quality of the window and door factory wear insulation strips?

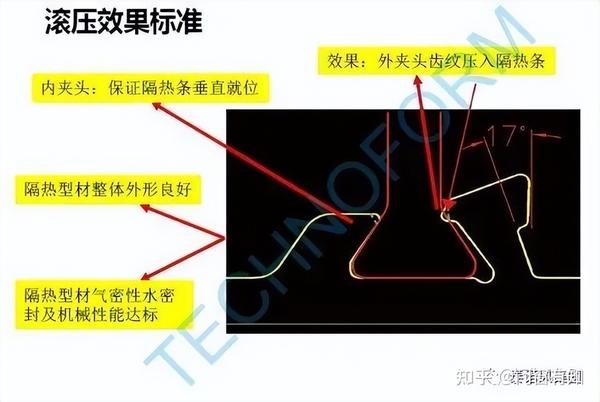

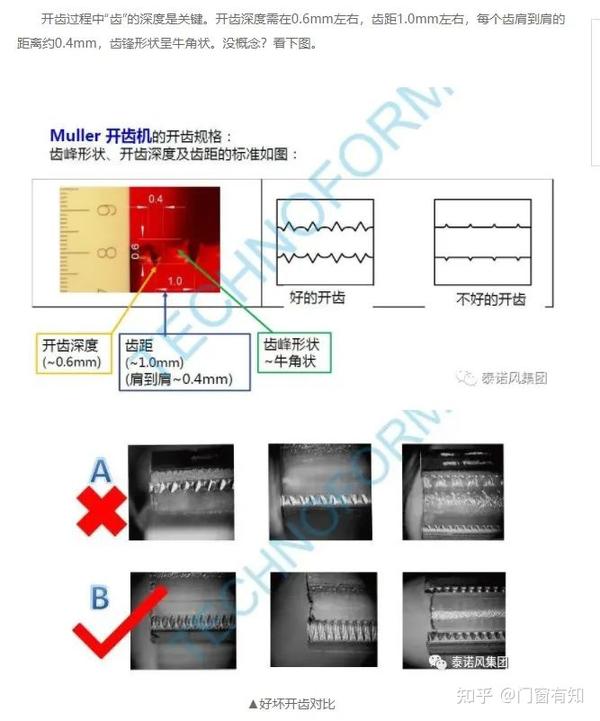

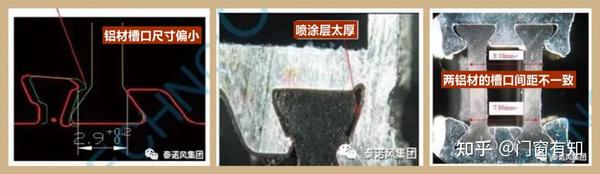

The formal threading process of the profile is – tooth opening, threading and rolling. The aluminium profile is first rolled over on a tooth-opening machine, so that a row of teeth is evenly distributed in the position of the insulation strip, in order to increase the roughness of the profile and improve the shear force of the composite profile. The heat insulating strip is then threaded into the grooves of the two aluminium profiles with the teeth cut (by hand or machine). The profile is then rolled by means of a rolling machine, so that the strip and the aluminium profile can be fitted and tightly connected. This is a fundamental part of the safe and effective use of aluminium profiles. A good process ensures that the airtightness, watertightness and mechanical properties of the profile are up to standard, and the national standard stipulates that the longitudinal shear strength of the profile should be greater than 24N/mm.

In some factories, the quality of the raw material is not good enough and the operation is not standardised, which can easily lead to problems such as the combination of heat insulation strips and aluminium profiles not being tight enough. In some cases, the profile is not open to the teeth directly through the strip, which greatly affects the strength of the aluminum profile.

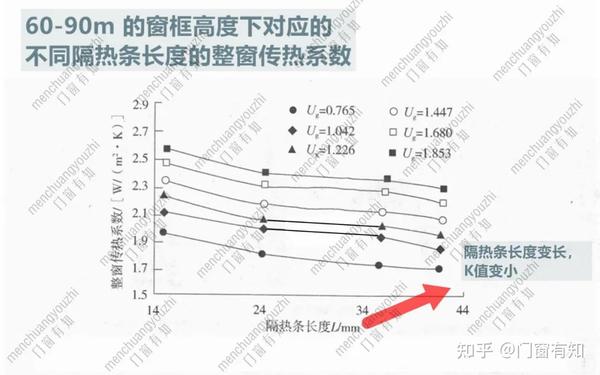

Does the width of the insulation strips determine the thermal insulation performance of the thermal-break profile?

Yes.

The overall K-value of a window or door is 20 – 30 % influenced by the frame (i.e. the aluminium profile), of which the heat transfer between the solids (the window or door frame) accounts for 50 % of the energy loss.

How should I choose between different insulation strip widths?

In the ideal budget situation, the wider the thermal insulation strip in bridged aluminium, the better, regardless of whether it is a single window or a window screen (except for sliding doors and windows, which are not the primary reference for performance). Generally speaking, it is best to choose products with a width of 20 mm or more, but below 20 mm the thermal insulation performance is too poor. If you have high thermal insulation requirements such as underfloor heating, choose a product with a strip width of around 30 mm or more.

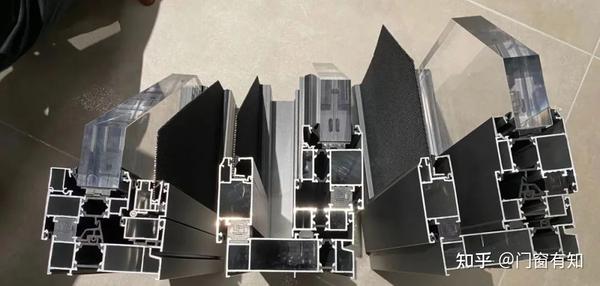

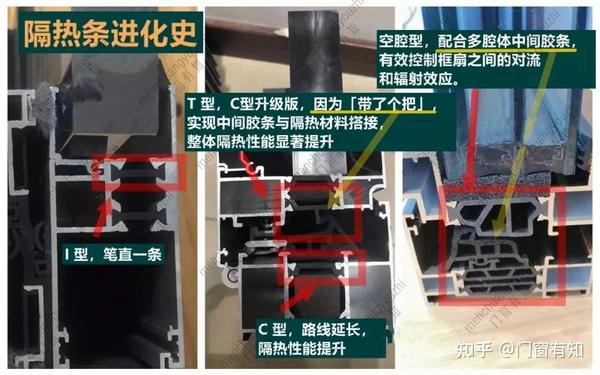

I see a lot of insulation strips that are not straight.

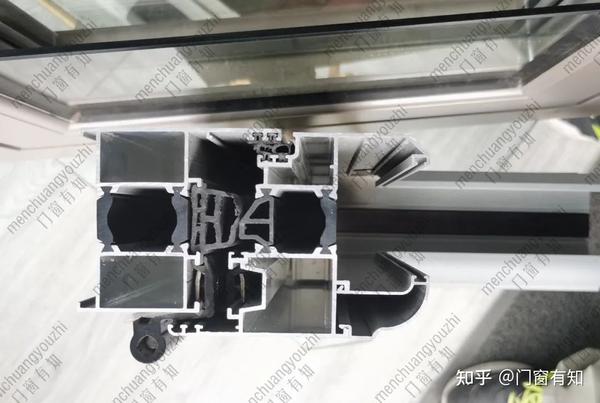

The 4 main shapes of insulation are I, C, T and cavity.

The I-shape is the original shape of the strip, straight and generally designed to be short in length.

The C-shape is a significant evolution of the I-shape and has a longer heat transfer path (better performance) than the I-shape for the same width. In terms of window and door products, Type C is better suited to the stepped drainage design of windows and doors, and has a flatter appearance in the location of the strip.

The T (or CT) strip is an evolution of the I or C strip, meaning that there is a small tail below the strip. In traditional window and door construction, the middle strip is lapped to the aluminium profile and the overall design is not optimised for thermal insulation.

With the advent of the T-shaped strip, it is possible to lap the intermediate strip with the insulation material, resulting in a significant increase in overall thermal insulation performance.

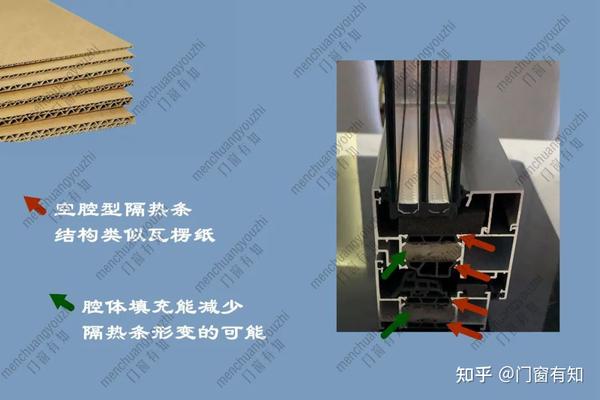

The cavity (or rib) type strip is another evolution of thermal insulation strips in recent years. As the thermal insulation performance of windows and doors has increased, the width of the strip has increased, in order to accommodate the strength of the wider strip and to achieve the increased performance of the whole frame due to the cavity cut / multi-cavity.

It can be seen that: ① when choosing a window or door, if there is a C type, do not choose the I type; ② T / CT type strips are exclusive to three-way sealed windows and doors, mainly to lap with the middle strip; ③ in the case of similar widths, cavity / rib type strips are often more advanced than C / T type; ④ when the width of the insulation strip is wider, it appears in the form of cavity / rib type strips.

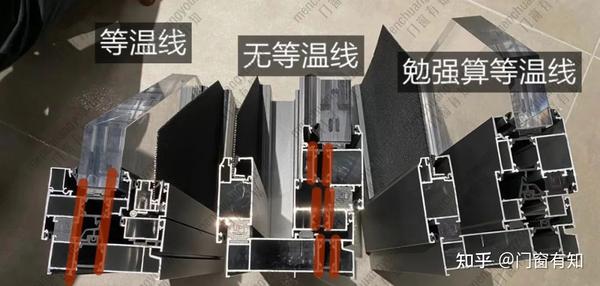

Is the insulation strip better as an isotherm?

Yes.

An isotherm (also called an isothermal layer) is when the insulation strips of the sash, frame and (attached frame) are all in the same straight line.

A window or door with an isothermal line is like a cold wall, which is better able to isolate the difference in temperature between the two sides of the window or door.

For windows and doors with high thermal insulation requirements, try to choose a structure with isothermal lines.

Is it useful to fill the cavity of an insulation strip with insulation wool?

Yes, it is!

Materials such as insulation wool, or polyurethane, are filled into the insulation strip cavity (and also under the glazing) to further reduce heat and cold transfer in that location.

However it is a higher-order requirement, like isothermal layers, and is more suited to windows and doors in homes such as underfloor heating, so if the product is of average construction or glazing configuration, there is no need for additional fittings.

Is the thicker the insulation the better?

No, generally good quality insulation strips are thinner, while poor quality strips look much thicker.

Wide and thin strips are best, but only if they are strong. If you want to ensure strength when making a poor quality strip wide, you have to add a thicker strip.

Is it bad if the insulation is too wide?

The width of insulation strips is increased without affecting their strength.

For example, I-shaped strips are generally not very wide (20 mm at most), as they tend to bend under stress and have no guarantee of strength.

The C, cavity type, etc. are the result of the widening of the strips, which provide better support (cavity type strips can be up to 40 mm).

In addition, the greatest weight of a window or door comes from the glass. A reliable installation of glass will have glass pads underneath, which will disperse the weight of the glass onto the internal and external aluminium frames.

Can I put screws on top of the insulation bars when installing windows and doors?

Never.

There are many potential problems with screwing in insulation. The ultimate strength of an insulating strip is only 1/4 of that of an aluminium alloy and is far less reliable than a screwed aluminium alloy. Screws can damage the thermal insulation of the strip, creating a thermal bridge and reducing the insulation performance of the window or door. Loose or rusty screws can cause leaks in windows and doors. No matter what the installer says to you, he is just trying to be lazy (screws in the insulation strip save effort), so pay attention to supervision when installing windows and doors.