Best Double Hung Windows

At Oridow, A double-hung window features two sashes, one on top and one at the bottom, which can be raised and lowered to allow fresh air into the room.

This type of window is excellent for improving air circulation since you can open both the top and bottom sashes. Warm air can escape through the top while cool air can enter through the bottom, providing better ventilation.

To provide wholesalers and contractors with a comprehensive guide to double-hung windows for their upcoming projects, this page will offer detailed information.

Aluminum Double Hung Windows

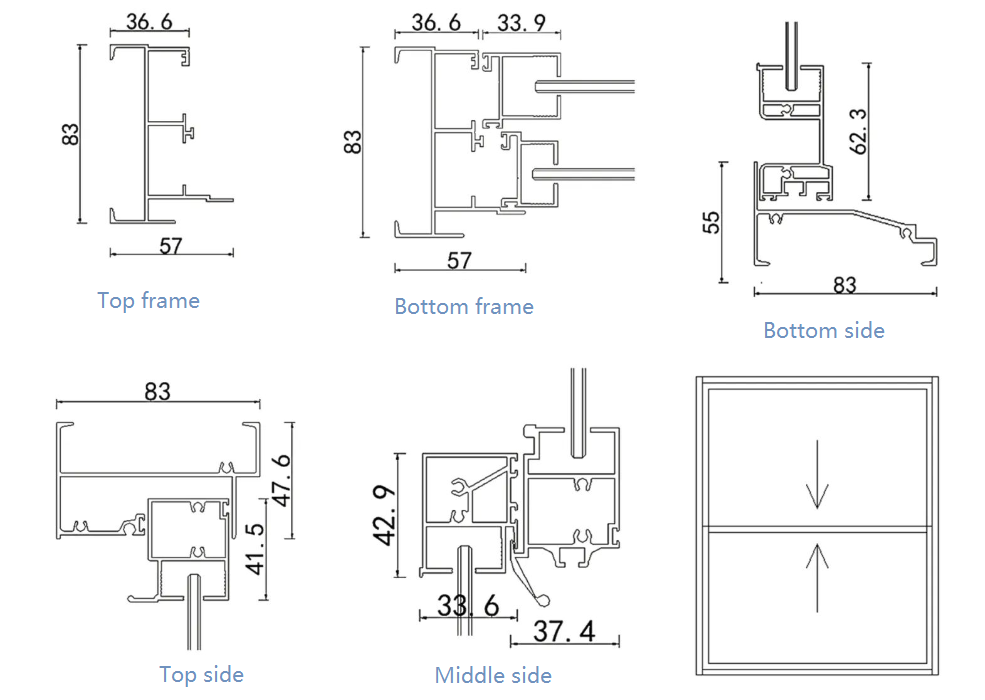

Our premium quality aluminum double-hung windows offer a perfect blend of style and functionality, making them an ideal choice for any modern home. They are available in both thermal break and non-thermal break options, depending on your specific requirements and preferences.

Our thermal break windows are designed to enhance energy efficiency and keep your home comfortable all year round. They feature a polyamide strip that separates the interior and exterior aluminum frames, preventing heat transfer and reducing energy consumption.

Our non-thermal break windows, on the other hand, offer exceptional durability and strength. They are perfect for environments where energy efficiency is not a top priority, but structural integrity is.

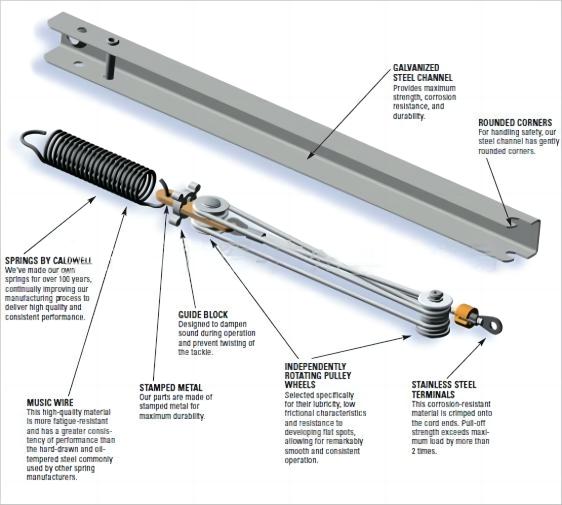

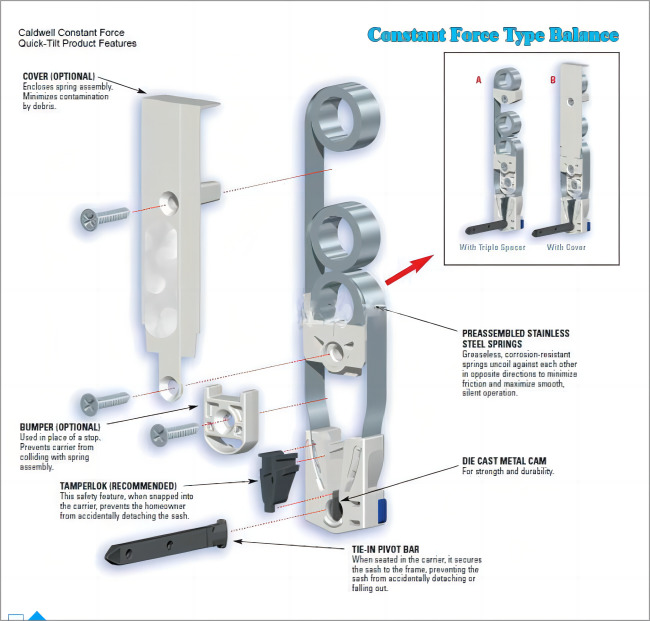

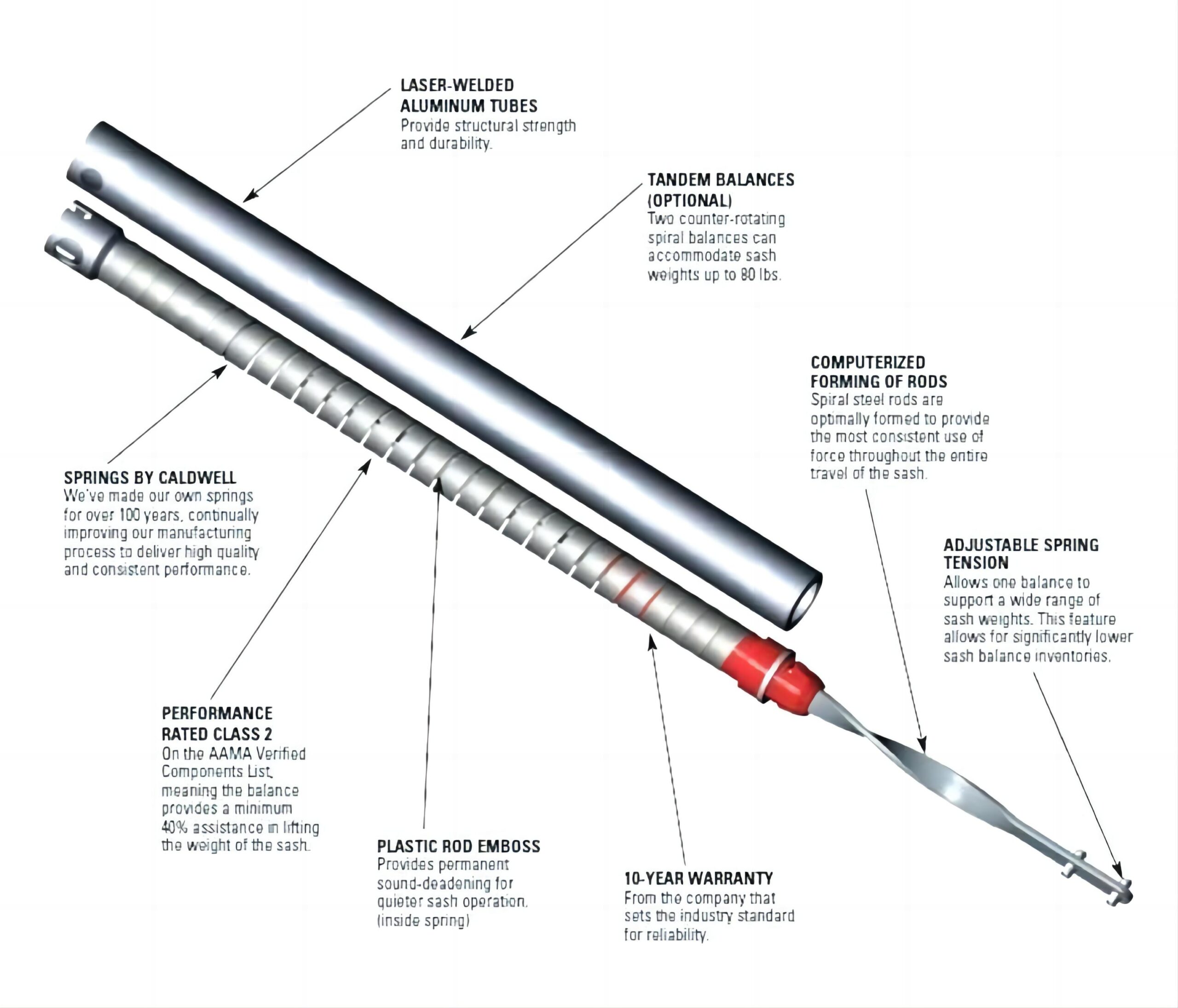

To ensure maximum loading ability, we offer an optional Caldwell balance that is designed to provide smooth and consistent sash operation. With our aluminum double-hung windows, you can enjoy a seamless blend of style, functionality, and durability that will last for years to come.

Caldwell Hardware for option

Customized Options

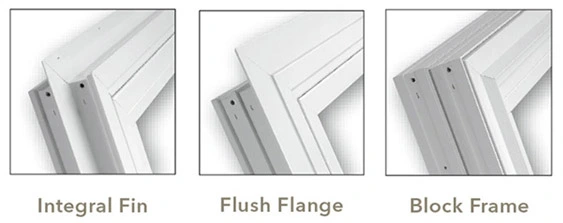

We provide three different frame: Integral fin, flush flange and block frame.

Energy efficient Insulated Low E Glass

This is the premium-grade glass we employ for our double hung windows. It consists of two layers of tempered glass, each measuring either 5mm or 6mm in thickness. One of these layers is treated with a state-of-the-art LowE coating for enhanced energy efficiency and insulation. Our partnerships are established with top-tier glass manufacturers renowned for their ability to supply a wide range of high-performance glass options, including triple silver, double silver, single silver Low-E glass, and composite glass solutions.

You can also read this post of All about LowE glass to know more about the LowE glass.

Additionally, we offer the option to customize lattice strips to match your specific requirements, ensuring that your fold up windows are not only functional but also aesthetically tailored to your preferences.

Double hung VS Single Hung

Double Hung window

Double-hung windows have both the upper and lower sashes movable and can be opened simultaneously.

This feature allows double-hung windows to offer better ventilation since they allow fresh air to enter through the bottom sash while simultaneously allowing warm air to escape through the upper sash.

Double-hung windows are much simpler to clean and maintain than single-hung windows. Because the sashes of double-hung windows tilt inward, it is possible to clean the glass on both the interior and exterior of the window without leaving your house.

Single Hung Window

Single hung windows consist of two sashes, with the top sash being fixed and the lower one being operable. This design allows for some amount of ventilation, but not as much as you would get with double hung windows.

Also, cleaning the outside of the top sash can be difficult if you live in a high-rise building.

However, single hung windows are usually more affordable than double hung windows because they only require one set of locking mechanisms. Single hung windows are cheaper than double hung windows at USD 10 per sqm.

Things you Need to Know about double hung windows

To save you from worries, here are some facts you need to know about our double hung windows

How much is the average double hung window?

For the non thermal aluminum double hung window with double glazed glass, the average price is USD

What materials are double hung windows available in?

Our double hung window is available in thermal break aluminum, non thermal aluminum and uPVC.

Common Issues With Aluminum Double-Hung Windows

Damaged Seal

During the cold weather, the windows may get fogged up and sometimes there is a smog that will not dissipate on its own. A tiny gap between the seal and the glass may develop as a result of the manufacturing process or impact damage.

Difficulty in Opening

Another common issue with aluminum hung-window is that sometimes the hinges attract dust and this makes it difficult to close or open the windows. However, lubricating the window hinges would help solving the issue.

Chilly Windows

The window sashes around the weather stripping likely need to be replaced if they frequently feel a draft emanating from them. Energy-efficient windows would be required to halt the draft.

How To Clean And Maintain Aluminum Double-Hung Windows

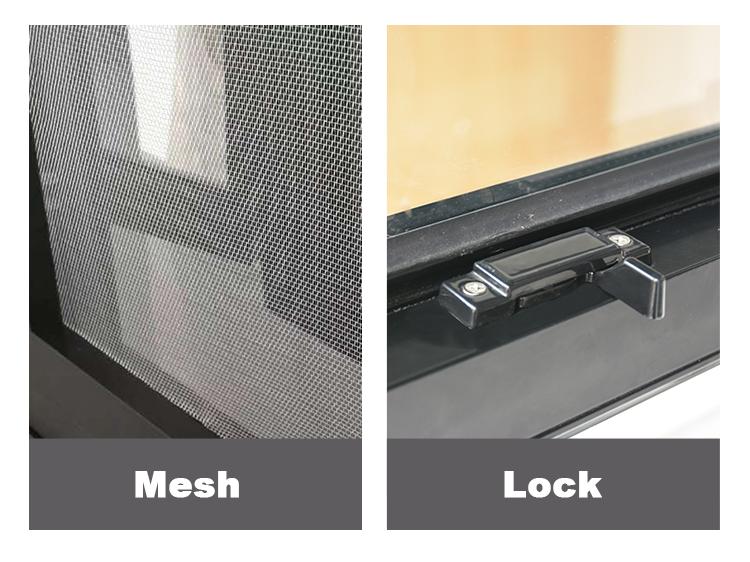

Screen Cleaning

Initially, take the screen out of the window frame. Dish soap and tepid water are combined. (mild option). You should dip a sponge into the concoction. Use the sponge to scrub the insect screen carefully.

To prevent damage, hold the insect screen cloth while cleaning it. Use tepid water to rinse it. Let it air for a while. Install it back into position after it has dried.

Casing cleaning

The casing should be cleaned frequently to remove grime and debris accumulation that can cause the windows to stick.

To ensure that the sash operates without difficulty, vacuum any grime and debris that may have amassed in the sill and track. Any vinyl window components should be washed with water and a gentle detergent.

Tips For Installing Double-Hung Windows

The proper installation is essential to ensuring that all doors and windows will continue functioning correctly and trouble-free for many years.

Before you begin, check that you are outfitted with the appropriate protective gear for the location where you will be operating and the instruments you will be using.

You will need the following instruments:

- Drill with a bit measuring 3 millimetres, which is used for pre-drilling the holes for the fixings.

- Hammering in nails or screwing in screws that are appropriate for your particular installation

- Spirit level

- Tape measure

- Hammers\Packers

- Tiny pinch bar

- Screwdriver with a flat head

- Staple gun and staples for flashing

- A second set of hands to help out (depending on the size and weight of the product)

Before Installation

Measure the product’s height, breadth, and depth, as well as the aperture it will be installed into, before commencing installation.

To ensure a square and level installation, the opening size has to be larger than the product by 20 millimeters in width and 30 millimeters in height. Please refer to the sample that may be seen below about spacing requirements.

The total depth of the product must correspond to the kind of cladding it will be fitted into. This was likely decided when the goods were purchased; nonetheless, it does not harm to check more than once. You must also decide what kind of flashings are necessary for the job. While we provide a selection of typical flashings, the builder must choose how the structure will be made waterproof.

It is necessary to advance the flashing and secure it to the front face of the stud. A standard staple gun may be used to do this task.

It is a good idea to check again to see whether the product you are installing has any particular installation criteria that must be followed. They could include customized head heights, unique finishing elements, or the ability to match other items.

You may start the installation when all of the checks have been double-checked.

Installing double-hung window

- To begin, position the pack level where the product will sit on the bottom plate and the spirit level where it will rest. If packers are necessary, secure them using brad nails to ensure they do not slide about.

- Make a mark on the reveal of both jambs one hundred millimeters down from the top and one hundred millimeters up from the bottom.

- Use a drill bit with a diameter of 3 millimeters to create a hole in each mark.

- Put the product in via the opening while it is still on the outside.

- Overhang the reveal back into the house by 10 millimeters, using a 10-millimeter packer or the thickness of a basic brickies ruler as a reference. A conventional installation allows 10 millimeters of plaster to be applied inside.

- Install a nail into the stud by driving it into the pre-drilled hole closest to the sill on both sides of the product.

Note: Do not completely hammer them in at this point.

- Insert a nail into the hole pre-drilled at the very top of the reveal. Remember, you should not hammer it in completely. On the other side of the product, repeat the same sentence.

- Check that the product is square and plumb by pressing your spirit level against the jamb while inspecting.

- To ensure the product is square, measure it diagonally in both directions. Both dimensions should ideally be identical to one another. However, a difference of up to a few millimeters is considered acceptable.

- Use the pinch bar to place the product into the appropriate position carefully if necessary.

- Examining how the product functions before packing it and putting it away are important. To check that the sash is operating correctly, slide it open and back into the closed position.

Finishing

When you are satisfied with the product’s location, pack between the reveal and the start above the nails, then hammer all the nails into place.

Get estimation for your project

We’ll be in touch with the information you provide to select the best choice for your project. Contact us today and get an estimation for your project!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!