Choosing an aluminum window manufacturer goes far beyond aesthetics or upfront cost. The right choice influences energy efficiency, structural performance, safety, and how well your property holds its value over time. In markets like Australia, the UK, and the USA, understanding what truly defines a reliable manufacturer has become increasingly important.

Whether you are renovating, building a new home, or selecting windows for a larger project, clarity makes all the difference. A clear understanding of what to evaluate and what to avoid helps ensure decisions that perform well long after installation.

What is a reliable aluminum window manufacturer?

A reliable aluminum window manufacturer is a company that consistently delivers certified products, proven performance, transparent warranties, and dependable after-sales support. They combine tested materials, precision engineering, and compliance with local building standards.

In practical terms, reliability means:

- Windows that perform as promised in real-world climates

- Consistent quality across every order

- Clear documentation, testing reports, and certifications

- Long-term support, not just a one-time sale

This definition matters because aluminum windows are a long-term investment, not a decorative upgrade.

Why manufacturer reliability matters more than window design

Aluminum windows are known for strength, slim profiles, and modern aesthetics. But knowing about real benefits matter more than appearance.

Industry data shows that poorly manufactured windows are among the top contributors to:

- Heat loss and higher energy bills

- Water and air leakage

- Hardware failure within 3–5 years

- Costly replacements or retrofits

As energy regulations tighten across Australia, the UK, and the US, manufacturers must meet stricter thermal and structural benchmarks. Choosing reliability upfront protects you from compliance issues later while improving comfort and performance from day one.

Key factors to evaluate before choosing an aluminum window manufacturer

1. Certifications and compliance standards

Always start with certifications. A trustworthy manufacturer openly complies with regional and international standards.

Look for:

- Thermal performance ratings suited to your climate zone

- Wind load, water penetration, and air infiltration test results

- Compliance with local building codes and energy regulations

Manufacturers that invest in testing are committed to performance, not shortcuts.

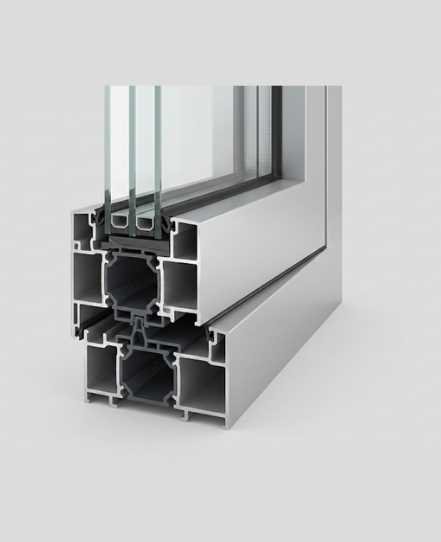

2. Quality of aluminum profiles and glazing systems

Not all aluminum is equal. The profile design, wall thickness, and surface treatment determine durability and efficiency.

High-quality manufacturers typically offer:

- Thermally broken aluminum profiles

- Multi-chamber designs for insulation

- Precision-engineered frames that resist warping

- Advanced glazing options including double or triple glass

You can explore how modern aluminum windows integrate these features for long-term performance.

3. Energy efficiency performance in real conditions

Energy efficiency is no longer optional. In markets like Australia, the UK, and the US, homeowners expect windows that reduce heat transfer and improve indoor comfort.

A reliable manufacturer designs systems that:

- Minimize thermal bridging

- Support low-E and argon-filled glazing

- Balance natural light with insulation

- Perform well in both hot and cold climates

Understanding real-world energy efficiency of aluminum windows helps you compare manufacturers beyond surface claims.

4. Customization and engineering capability

Every home and project is different. A strong manufacturer can adapt systems to your needs without compromising performance.

Evaluate whether they offer:

- Custom sizes and configurations

- Sliding, casement, tilt-and-turn, or lift-and-slide options

- Flexible finishes and color treatments

- Engineering support for large openings or architectural designs

A well-developed product range usually reflects deeper manufacturing expertise.

5. Manufacturing process and quality control

Ask how windows are actually made. Reliable manufacturers maintain tight control over every production stage.

Signs of strong quality control include:

- In-house extrusion or verified supplier partnerships

- Automated cutting and assembly processes

- Multiple inspection checkpoints

- Batch traceability and documentation

Consistency matters as much as innovation.

6. Warranty structure and after-sales support

A warranty tells you how confident a manufacturer is in their product. Short or vague warranties often signal risk.

Prioritize manufacturers that provide:

- Clear coverage terms for frames, glazing, and hardware

- Realistic warranty durations

- Accessible support channels

- Replacement or repair procedures that are easy to follow

Strong support protects your investment long after installation.

Industry trends shaping aluminum window manufacturing

Modern aluminum window manufacturing is evolving fast. Understanding these trends helps you identify forward-thinking suppliers.

Key trends include:

- Increased demand for thermally broken systems

- Growing focus on sustainability and recyclable materials

- Slimmer profiles paired with higher structural strength

- Smart integration with shading and ventilation systems

Manufacturers aligned with these trends tend to deliver better long-term value.

Common mistakes to avoid when selecting a manufacturer

Every project is different, and choosing the appropriate system requires manufacturers that can adapt without compromising performance. Even experienced buyers make avoidable mistakes. Watch out for these red flags:

- Choosing solely based on price

- Ignoring local compliance requirements

- Overlooking installation compatibility

- Failing to review sample units or test data

- Assuming all aluminum windows perform the same

Educated decisions reduce costly surprises later.

Reliable vs unreliable manufacturers at a glance

| Evaluation Area | Reliable Manufacturer | Unreliable Manufacturer |

| Certifications | Clearly documented and verified | Vague or missing |

| Energy performance | Tested, climate-appropriate systems | Generic performance claims |

| Profile design | Thermally broken, engineered | Basic hollow profiles |

| Customization | Flexible without performance loss | Limited or risky modifications |

| Quality control | Multi-stage inspections | Minimal checks |

| Warranty | Transparent and detailed | Short or unclear |

| Support | Responsive and knowledgeable | Difficult to reach |

Why Oridow is the right supplier for aluminum windows

Oridow stands out by combining engineering precision with real-world performance. The company focuses on manufacturing aluminum window systems that meet demanding energy, durability, and design expectations across global markets.

What sets Oridow apart:

- Advanced thermally broken aluminum systems designed for energy efficiency

- Precision-manufactured profiles that support large spans and modern architecture

- Comprehensive glazing options optimized for different climate zones

- Rigorous quality control from material selection to final assembly

Their approach reflects a deep understanding of what homeowners and professionals need from modern window systems. Beyond product quality and a wide range, Oridow places strong emphasis on transparency and long-term support. Detailed technical documentation, flexible customization options, and a responsive service approach help simplify what can otherwise be a complex selection process. For homeowners or professionals exploring tailored solutions, starting a conversation with Oridow’s team can provide valuable clarity at the right stage of planning.

How to compare manufacturers side by side

Use this simple framework when narrowing your shortlist:

- Performance data over marketing claims

- Certifications over assumptions

- System design over surface aesthetics

- Long-term support over short-term savings

This approach works consistently across residential and commercial projects.

Frequently Asked Questions

How do I know if an aluminum window manufacturer is trustworthy?

Look for certifications, third-party testing, clear warranties, and transparent technical documentation. Consistent quality control and responsive support are strong indicators.

Are aluminum windows suitable for cold and hot climates?

Yes. When designed with thermal breaks and high-performance glazing, aluminum windows perform well in both extreme heat and cold.

What certifications should aluminum windows have?

This depends on your region, but generally includes thermal performance ratings, air and water resistance tests, and compliance with local building codes.

How long should aluminum windows last?

High-quality aluminum windows can last 30 to 40 years or more with proper installation and maintenance.

Is customization important when choosing a manufacturer?

Absolutely. Reliable manufacturers offer customization without compromising structural integrity or energy performance, ensuring the windows fit both design and functional needs.