Lowe glass is Low Emissty GIass for short, is a kind of coated glass (sunlight control, low radiation, conductive glass), and is a member of the building energy-saving glass.

The process principle of Low E glass is to coat the surface of the glass substrate with a multi-layer metal (silver, copper, tin, etc.) or other compounds with low radiation characteristics, and reduce the radiation rate on the glass surface through the coating layer, thus achieving energy-saving effects.

What is meant by offline & online Low E glass

According to the difference of preparation process, Low E glass is further divided into 2 types: offline and online Low E glass.

- Offline Low E is prepared by the “physical method”: the solid material is transferred to the glass surface and precipitated into a thin film by the plasma gas formed by the negative high voltage and working gas in a vacuum environment. Since the coating process is done in a separate coated glass line, it is called “off-line Low E glass”.

- In-line Low E prepared by “chemical method”: Low E films made by chemical vapor spraying in the high-temperature zone of glass forming in the production line for float glass.

Differences in use and performance between offline and online Low-e glass

The difference in film layer and process makes the difference in use and performance between offline & online Low E glass:

Offline Low E glass features

- offline Low-e is a silver film (silver plating layer, silver ions), that is what factories mentioned single silver, double silver, and triple silver, are offline Low-e glass.

- Offline Low E film layer is afraid of abrasion and corrosion, and metal silver ions are afraid of oxidation, so it is basically used with insulating glass (the film layer is placed on the inside of the insulating glass to prevent oxidation, and now new technology has also emerged without silver offline Low E, which can not be used together with insulating glass, but less).

- Off-line Low E glass with better thermal insulation performance and a glass surface emissivity of less than 0.15.

- Certainly, here’s an improved version of your content:

- When it comes to home furnishings, many offline Low E glass processing plants prefer to acquire raw sheets of toughenable offline Low E glass for their production needs. Additionally, these plants often opt for customization services to obtain precisely tailored toughened offline Low E glass solutions.

Features of online Low-e glass

- Online Low E film is non-silver (such as tin oxide), and is equivalent to one with the glass, the film layer is high temperature resistant, corrosion resistant, not afraid of abrasion, all can be directly toughened, can be used directly single piece.

- Online Low-e glass heat insulation and thermal performance is relatively poor, the glass surface emissivity of about 0.17 -0.22.

- Because of convenience and other factors, online Low-e film is also used by glass deep processing plants.

What is low E ? What is the surface emissivity of glass?

The above section has raised the emissivity many times, then what is low radiation, surface emissivity? What is the difference between an emissivity below 0.15 and above 0.15?

Radiation Rate

Radiation rate is hemispherical radiance, is the ratio of the radiation emissivity of the radiation object and the radiation emissivity of the Planck radiator at the same temperature.

Low Emissivity

Physics classifies all objects with emissivity below 0.15 (also written 15 %) as low emissivity objects.

Surface Emissivity

The surface emissivity of glass is the hemispherical emissivity of glass, which is a measure of the ability of the glass surface to absorb radiant energy to reach equilibrium and then radiate energy to the outside (think of it as water being boiled to 100 ° and then only releasing water vapor to the outside). The lower the emissivity, the less heat is absorbed by the object, and the less heat is released to the outside.

Is online Low E low emissivity?

Off-line Low E glass has an emissivity of less than 0.15 and is undoubtedly considered “proper” Low E glass.

Ordinary glass generally has an emissivity of 0.84, while in-line Low E glass has an emissivity of about 0.17-0.22. Therefore, strictly speaking, in-line Low E glass is not considered low E glass, so it has another exclusive term, “K glass”.

However, because in-line Low E emissivity is also much lower than that of ordinary glass, most of the time it is also referred to as low-emissivity Low E glass.

How does Low E glass insulate and keep warm?

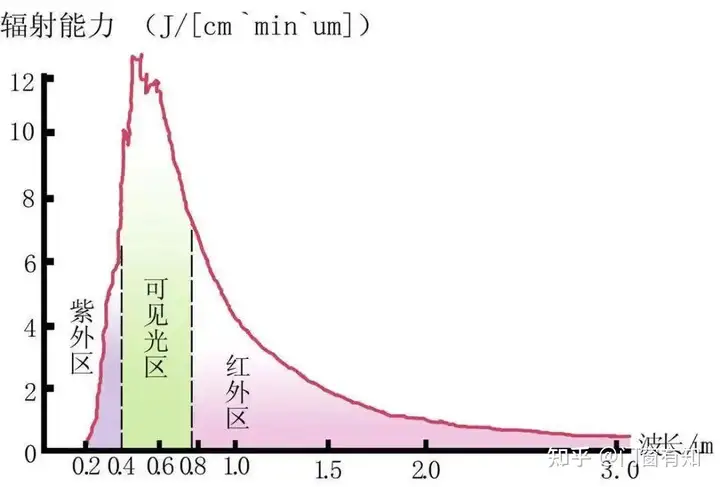

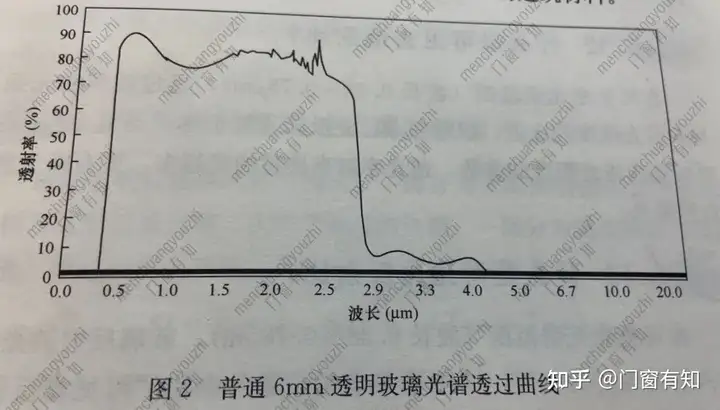

In the natural environment, there are 2 forms of radiant energy related to glass energy efficiency: solar radiation and far-infrared radiation.

Solar radiation

Solar radiation energy, which is sunlight, is divided into ultraviolet radiation, visible radiation, and infrared radiation.

- Ultraviolet radiation, energy accounts for about 3 % of the total energy of solar radiation, the wavelength of 0.3 ~ 0.38 μm (read micron, wavelength unit), and ultraviolet radiation is not visible to the human eye.

- Visible radiation, energy accounts for about 47 % of the total energy of solar radiation but is not the main carrier of heat energy, the wavelength of 0.38 ~ 0.78 μm, visible light is visible to the human eye (red, orange, yellow, green, blue, violet).

- Infrared radiation, energy accounts for about 50 % of the total energy of solar radiation, is the main carrier of heat energy, wavelength of 0.78 ~ 2.5 μm, infrared radiation is not visible to the human eye but can feel the heat sensation.

Far infrared radiation

Far infrared radiation energy is any object with temperature to the outside of the heat radiation.

- Wavelength is greater than 2.5 μm, radiation wavelength range is generally 2.5 ~ 50 μm. The higher the temperature of the object emitted by the heat radiation the hotter the human body feels.

- In summer, the outdoor temperature is high, and objects such as the atmosphere, roads and buildings are heated by the sun, and then the heat released to the outside world is far-infrared radiation, which is transmitted into the room.

- In winter, the indoor temperature is high, the heating, electrical appliances and human body release far-infrared radiation to the outside world, which is transmitted to the outdoors.

How to evaluate the thermal insulation performance of glass?

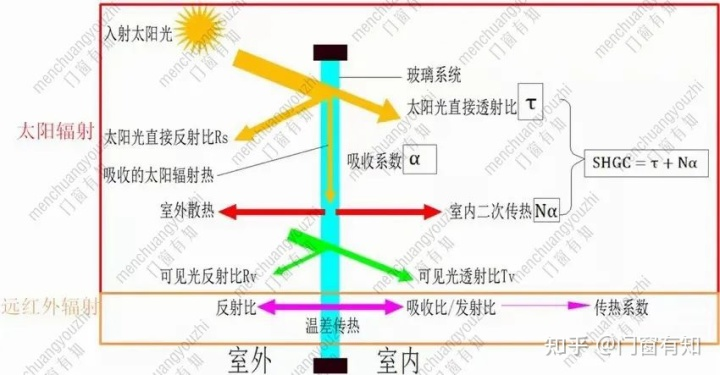

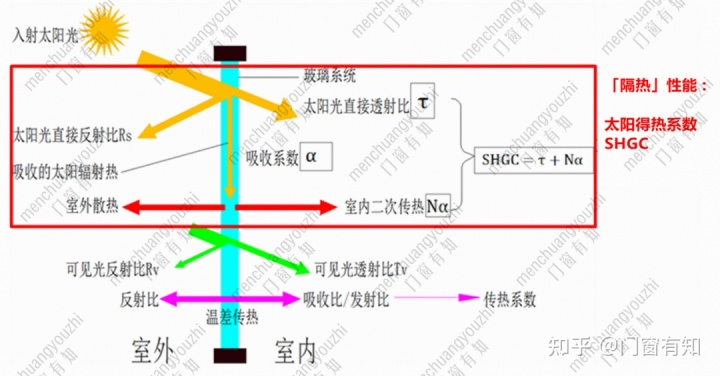

Currently, the solar heat gain coefficient SHGC is commonly used internationally.

- Solar Heat Gain Coefficient (SHGC) is the ratio of the total energy of solar radiation through the glass (including the energy of direct solar irradiation through the glass, and the energy of secondary radiation to the room after heat absorption by the glass) to the energy of incident solar radiation.

- In layman’s terms, a piece of glass is more insulated if it reflects more sunlight (i.e. solar radiation, same below) and lets in less solar radiation, or if the glass absorbs less heat and lets in less secondary heat transfer to the room.

- The solar heat gain coefficient SHGC is the total solar transmittance ratio g. The shading coefficient (Sc), another parameter for evaluating thermal insulation, can be converted with the total solar transmittance ratio (g) value (g = 0.87 Sc).

To evaluate the thermal insulation performance of glass, there is another parameter indicator, namely the heat transfer coefficient of glass (K value, U value).

The heat transfer coefficient of glass (K value) is the amount of heat passing through a unit area of window, door or curtain wall per unit time under steady-state conditions when the difference in an ambient temperature between the two sides of the glass is 1 K (without considering the influence of the glass edge).

In common parlance, a piece of glass that absorbs less heat to make the secondary heat transfer in the room less, or reflects more far-infrared radiation and absorbs less far-infrared radiation, will be more insulated.

The low emissivity of Low E glass is the key to its superior thermal insulation performance

- When the solar radiation shines on the glass surface, the sum of the three reflected, absorbed and transmitted by the glass is equal to the solar radiation, i.e. the glass reflectance + absorption + transmission = 100 %;

- And because the glass reaches an equilibrium state, how much absorption, how much radiation outward, so there is: absorption rate = radiation rate.

- Low E glass reduces the secondary heat transfer in the room through low absorption (low emissivity) and high reflection of solar radiation to reduce the direct heat transfer through solar radiation (the following figure ▽), which greatly improves the thermal insulation performance parameters of the glass.

The low emissivity of Low E glass also plays a role in thermal performance.

- The low absorption of solar radiation (low emissivity) reduces the secondary heat transfer in the room.

- The wavelength range of heat energy emitted by far-infrared radiation is generally in the range of 2.5 ~ 50 μm, and the glass only has transmission of far-infrared radiation in the low wavelength band, most far-infrared radiation glass will transfer heat through the glass by first absorbing (glass temperature increases), and then radiating (itself into a high-temperature object convection and radiation heat transfer).

- Low-e glass low absorption rate (low emissivity), far-infrared radiation is not transmitted, which means that most of the far-infrared radiation is reflected (so in winter, Low E glass in the room without the sun can also play a role in insulation, reflecting the far-infrared radiation in the room).

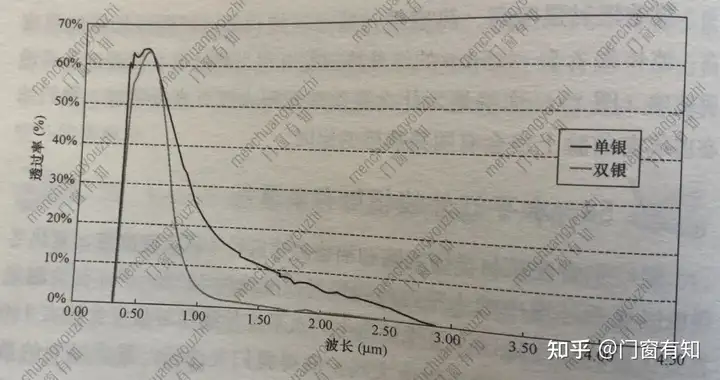

What is double silver, triple silver Low-E glass?

- Ordinary offline Low E only contains a single layer of silver film, double silver and triple silver can be directly understood as the upgrade of single silver Low E (superimposed silver film layer).

- Multi-silver blocks more solar infrared radiation transmission, i.e. better thermal insulation (whether it is solar heat gain coefficient SHGC, solar shading coefficient Sc, or total solar infrared heat transmission ratio gIR).

- More silver film has a lower radiance and therefore a higher heat transfer coefficient (not as pronounced as the thermal insulation improvement).

Why do doors and windows factories often recommend Low E insulating glass?

- Ideal effect, Low E insulating glass is similar to triple glazing in thermal insulation and better than triple glazing in heat insulation;

- Affordable, insulating glass with Low-e costs about 50 ~ 100 yuan per square meter, which is more affordable than triple-glazing glass;

- Easy to use: The glass is light, easy to transport and install (save labor), also convenient for design and subsequent use.

Why is there no Low E laminated glass?

Because the Low E film layer has poor performance if it is inside the laminated layer. Only when the Low E film layer is in contact with the air, it can effectively reduce the heat exchange between the glass surface and the air, thus improving the heat insulation effect, so the two products do not match when put together.

How to choose the light transmittance of Low E glass?

- Low E glass light transmission performance parameters, you can refer to the visible light transmission ratio, also known as light transmittance. The higher the light transmittance, the more natural light it helps the room. General level can be divided into high, medium and low transmission three kinds (more than 70 %, 50-60 %, 50 % and below);

- Low E glass light transmission has almost no effect on the insulation performance, has a certain impact on the insulation performance. The lower the light transmittance, the better the relative thermal insulation performance (solar heat gain coefficient SHGC = direct solar transmittance ratio + indoor secondary heat transfer, direct solar transmittance ratio of solar radiation intensity to incident intensity);

- Low E glass light transmission is certainly not as good as white glass (light transmission rate of 85-90 % or so), the most generally considered at home or a higher light transmission rate of Low E glass, low light transmission rate of the sunroom applications are mostly.

- The opposite of light transmission is reflectivity, so the lower the light transmission must represent the better the privacy of the glass.

The service life of insulating Low E glass

- In the qualified and compliant insulating glass, the air is dry and the dew point is very low (- 40 ℃, the dew inside the insulating glass means that the glass is useless), in such an environment the use of Low E film is stable and theoretically can be equal to the effective life of insulating glass.

- The above premise requires that the coating is fine, the production process of Low E insulating glass is standardized, and the finished glass is of good quality.

- And if the original Low E glass is not produced in a timely manner or reasonably preserved, inferior Low E glass original (thin protective film, etc.), the production of the part of the sealant coating is not removed from the film or not removed thoroughly, Low E film scratched, or insulating glass production and production problems (poor sealant used, uneven coating of butyl glue, spacer molecular sieve quality is too poor, etc.), may lead to insulating Low-e glass effective service life is short (two or three years failure of many).

- Therefore, when consumers purchase insulating Low E glass, they should first confirm the quality of the finished glass by asking the merchant “what is the deep processing of the glass and what supply chain is used”.

- Secondly, by asking the merchant “Is there a factory processing video? What is the strength of the factory? Is the degree of equipment automation high? How about quality control?” etc. to understand the processing capability of the glass processing factory.

- Or ask the merchant “Do you provide a warranty for insulating Low-e insulating glass? How many years is the warranty?

What homes are suitable for Low-e glass?

The performance of windows and doors (glass) such as heat insulation and thermal insulation is to make the home environment more comfortable and livable. The premise of the performance of the first is to close the doors and windows, and have good sealing. Secondly, when the temperature difference between indoors and outdoors is relatively large, the home will be long-term cooling or heating.

Also, take into account Low E glass is expensive, reducing the light transmission of the glass, winter is not conducive to natural indoor heating, so Low-e glass is less suitable for the following areas:

- Those cities warm in winter and cool in summer

- Those used to always open the window for ventilation

- Those whose cooling or heating time is not long

- Those who just seal the balcony, other locations do not change the doors and windows, and the glass is not Low E

- Those who mainly choose sliding doors and windows (poor sealing)

- Those who live on a low floor, poor lighting

- Those who want to enjoy the warm sunlight even through the glass in winter

- Those who spend a short time at home (especially during the day)

Other than that, basically all homes are suitable for Low-e glass.

Low-e insulating glass, which side of the film layer position is appropriate?

Low E glass is most commonly used with insulating glass, and the location of its film layer is somewhat important:

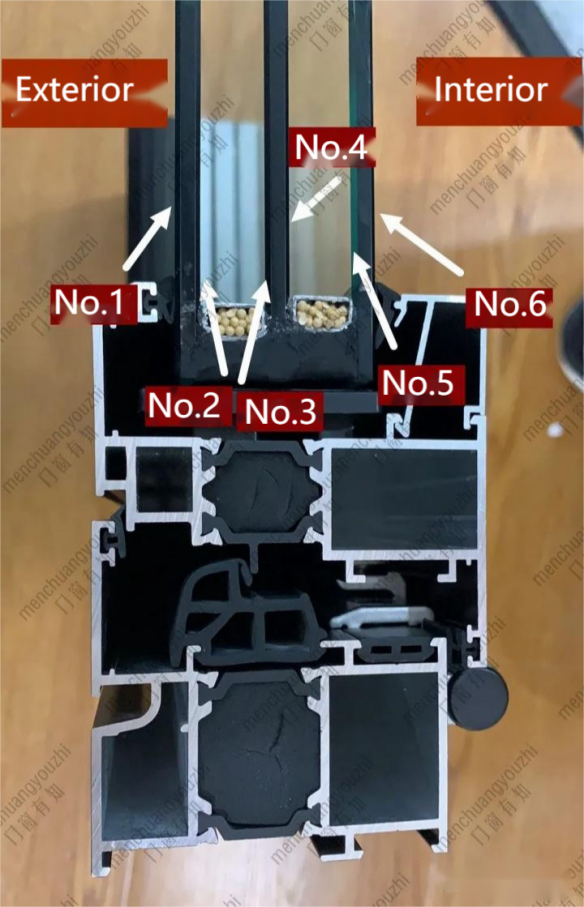

- Off-line Low-e film is located on the inner surface of the insulating glass, i.e. side 2 or 3 (and possibly side 4 or 5 for triple-glazing glass).

- For each hollow layer of insulating glass, only one glass surface needs to have a Low-e film, and having both surfaces does not significantly improve the energy-saving performance.

- The production and installation position of the film layer has an impact on the heat insulation performance (about 10-15%), for the southern cities or the pursuit of heat insulation effect, the film layer is suitable for the outside of the room (No.2 or No.4 side). In northern cities, because the solar heat demand is higher in winter than in summer, the membrane layer is suitable for the outside of the room (No. 3 or No. 5 side).