Key Takeways:

-

Vertical folding windows use hinged panels that fold vertically, maximizing space and creating large open connections.

-

These windows enhance design versatility, serving as exterior walls, room dividers, or pass-through counters in diverse settings.

-

They improve efficiency by increasing natural light, ventilation, and energy savings while supporting sustainable construction practices.

-

Builders and businesses benefit from space optimization, aesthetic flexibility, and seamless indoor–outdoor integration.

Vertical Folding Window for Builders and Businesses: Modern architecture never ceases to surprise us due to its ever-evolving nature. The 21st-century builders are always scouting for ways to maximize space and offer a unique style to their architecture. Due to this, a remarkable trend is emerging – the “Vertical Folding Window.”

These ingenious windows offer a transformative solution to businesses’ and builders’ space and style concerns. As urban spaces become more compact and design aspirations soar sky-high, the vertical folding window offers an easy solution.

A fusion of space optimization and contemporary elegance, vertical folding windows are poised to revolutionize the architectural landscape. It ushers in a future where functionality seamlessly intertwines with style.

This article delves into the captivating world of these windows. We shall focus on its advantages and immense potential for builders and businesses.

Defining and Understanding Vertical Folding Windows

Vertical bifold windows comprise multiple hinged framed panels that move vertically atop one another. It’s often called a vertical bifold window and represents modern architectural marvels. A vertical folding window offers innovative engineering solutions with higher aesthetic appeal.

These windows are designed to fold vertically along a track, creating a concertina effect that seamlessly connects indoor and outdoor spaces.

The vertical folding mechanism has a special feature. It allows the windows to be neatly stacked on one side. This action creates a large opening. It blurs the lines between indoor and outdoor spaces.

Advantages of Vertical Folding Window

As we go deeper into vertical folding windows, something becomes clear. These windows possess clever operation, flexible style, and a break from the usual ways. This makes them stand out as a crucial part of modern architecture.

Here are some of the prime advantages these windows offer to builders and businesses:

Operational Mechanics

One of the prime advantages that vertical folding windows offer is the ease of operations. Using a series of interconnected panels, these windows smoothly fold and unfold.

The panels are mounted on a track system, ensuring seamless gliding motion. This mechanism provides minimal space while delivering a wide opening, encouraging a seamless transition between living spaces and the outdoors.

Versatility in Design and Placement

One of the most compelling aspects of vertical folding windows is their adaptability to diverse design styles and architectural contexts.

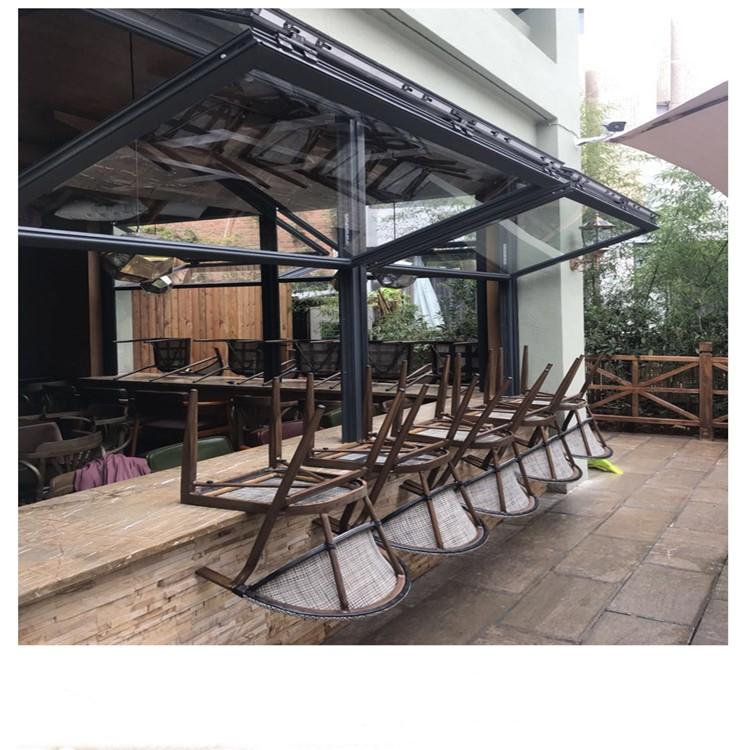

Whether integrated into residential homes, commercial establishments, or hospitality spaces, these windows effortlessly elevate the aesthetics of any environment.

Their versatility extends to placement options as well. Vertical folding windows can be employed as exterior walls, room dividers, or even pass-through counters, offering a unique blend of practicality and visual appeal. This is especially beneficial for builders and businesses.

Distinguishing from Traditional Window Types

Unlike regular windows, vertical folding windows are quite different in how they look and function. Fixed windows usually have just one fixed frame. However, vertical folding windows use a flexible folding mechanism. This lets them fully open up, letting air and light flow naturally.

Furthermore, these windows can uniquely transform spaces. They make it easy to blend indoor and outdoor areas. This goes beyond traditional windows, which usually remain static and compartmentalized.

Vertical Folding Window: A Boon for Builders and Businesses

Efficient Space Utilization

Builders and businesses find vertical folding windows lucrative since they offer effective space utilization in all structures. A vertical folding window can maximize space without compromising aesthetics and functionality.

In areas where traditional windows might encroach on valuable interior space, folding up windows ingeniously tuck away to the side. It allows for unobstructed usage of both indoor and outdoor areas.

This innovative approach allows architects and builders to maximize the available area while maintaining an open, airy ambiance.

Enhanced Natural Light Infiltration

One of the standout advantages of vertical folding windows is their ability to usher in abundant natural light. With their expansive openings, these windows create a seamless pathway for sunlight to permeate indoor spaces.

The increased natural light penetration not only contributes to a visually inviting atmosphere but also offers tangible benefits in terms of energy efficiency.

Reduced reliance on artificial lighting during daylight hours can lead to significant energy savings, aligning with the growing emphasis on sustainable design practices and Productivity through Open Spaces.

The incorporation of fold up windows goes beyond architectural aesthetics. It has a direct impact on the productivity of business environments. The connection between open, well-lit spaces and enhanced productivity is well-established.

Vertical folding windows facilitate the creation of such spaces by seamlessly merging indoor and outdoor realms. Employees and occupants are exposed to an environment stimulating creativity, concentration, and well-being.

Energy Efficiency

Vertical folding windows emerge as a beacon of innovative design in pursuing energy efficiency and sustainability.

Enhanced Ventilation and Temperature Control

By fully opening, the vertical folding windows facilitate the inflow of fresh air, promoting natural cross-ventilation. This strategic airflow improves indoor air quality and helps regulate temperature, reducing the need for energy-consuming cooling systems.

The windows can be opened wide in warmer seasons to create a refreshing breeze. While in colder months, they can be partially opened to maintain a comfortable and well-ventilated interior.

Sustainable Construction in Focus

Vertical folding windows represent more than just an architectural innovation. They symbolize a commitment to a greener and more sustainable future.

As the world increasingly emphasizes reducing environmental impact, buildings that embrace energy efficiency and sustainable design stand as beacons of responsible construction.

Architects, builders, and occupants collectively contribute to sustainable construction practices by integrating these windows into the fabric of their spaces. In essence, the benefits of vertical folding windows extend beyond the physical boundaries of the structure.

Final Thoughts

In the ever-evolving world of architecture, where form meets function, the emergence of vertical folding windows marks a transformative shift in design paradigms.

Vertical folding windows represent the synergy of two essential aspects: efficient space utilization and contemporary style.

By seamlessly melding these elements, these windows offer a glimpse into the future of architecture. One where spatial constraints are ingeniously overcome without sacrificing aesthetics.

Builders and businesses have a unique canvas to craft environments seamlessly blending indoor and outdoor realms, ushering in openness and well-being.

Companies like Oridow are at the forefront of this movement, specializing in innovative folding window and door solutions that redefine how spaces look, feel, and function. With a strong focus on durability, customization, and energy efficiency, Oridow delivers products that align with modern architectural needs while promoting sustainable building practices.

FAQs

1. Are vertical folding windows safe and durable for commercial use?

-

Yes, most vertical folding windows are made from aluminum frames that are strong, lightweight, and corrosion-resistant.

-

Safety glass can also be integrated, ensuring durability in high-traffic commercial spaces.

2. Do vertical folding windows leak during heavy rain or storms?

-

Properly installed vertical folding windows with weather-sealed frames prevent leakage.

-

High-quality models include drainage systems and gasket seals for protection against wind and water.

3. How much maintenance do vertical folding windows require?

-

They require minimal maintenance:

-

Regular cleaning of glass and frames

-

Occasional lubrication of the folding track and hinges

-

-

Aluminum frames resist rust, making upkeep simple.

4. Are vertical folding windows energy efficient in all climates?

-

Yes, they enhance ventilation in summer and allow partial openings in winter.

-

With proper glazing, they provide insulation, reducing dependency on heating or cooling systems.

5. Can vertical folding windows replace entire walls?

-

Yes, they are often used as movable glass walls in modern architecture.

-

They provide seamless indoor–outdoor integration without permanent barriers.

6. What is the cost of installing vertical folding windows?

-

Costs vary by:

-

Material (aluminum vs. wood or steel)

-

Size and customization (single panel vs. wall-length systems)

-

Glazing type (double/triple-pane for insulation)

-

-

Generally more expensive than traditional windows, but the space, light, and design benefits often justify the investment.

7. Are vertical folding windows difficult to operate?

-

No, they use a track system with hinged panels, making folding and unfolding smooth.

-

Even large panels can be opened with minimal effort.

8. Where are vertical folding windows most useful?

-

Ideal for:

-

Restaurants & cafés (pass-through service counters)

-

Offices & co-working spaces (flexible layouts)

-

Residential homes (balcony/patio openings)

-

Hospitality spaces (resorts, lounges)

-

9. Do vertical folding windows affect indoor air quality?

-

Yes, positively.

-

When fully open, they increase cross-ventilation, improving air circulation.

-

Reduces reliance on air-conditioning, lowering energy costs.

10. Can vertical folding windows be customized?

-

Absolutely. They can be tailored for:

-

Frame finishes (powder-coated aluminum in different colors)

-

Glass options (tinted, frosted, or clear)

-

Size and panel count (small counters to full glass walls)

-