Many people wonder about faux wood in home decor and construction. Knowing what faux wood is helps you make better choices. Faux or engineered wood looks like real wood but is made of synthetic materials.

The benefits of faux wood are many. It’s important to learn about faux wood to see its advantages.

People often ask about the benefits of faux wood. Knowing about faux wood helps you see its value. Oridow helps people explore faux wood and its possibilities.

Key Takeaways

- Faux wood is a synthetic material that mimics the appearance of real wood.

- Understanding the definition of faux wood is essential for making informed decisions.

- The benefits of faux wood include durability and low maintenance.

- Faux wood is a cost-effective alternative to real wood.

- Companies like Oridow offer high-quality faux wood products.

- Understanding faux wood is key to appreciating its value in various applications.

- Faux wood is a versatile material with numerous applications.

Understanding What Exactly is Faux Wood

Faux wood, also called engineered wood, looks like real wood but isn’t. Its meaning changes depending on where you use it. It’s a fake or mixed material that looks like wood. To understand faux wood, we need to look at its basic parts and how it’s made.

The types of faux wood include hardboard, particleboard, and laminated veneer lumber. These are made from wood fibers, particles, or veneers stuck together. For example, hardboard is pressed wood fibers, and particleboard is glued wood particles.

Basic Definition and Components

Faux wood is a mix of materials and making processes. It can be made from wood scraps, sawdust, and other cellulose. The parts of faux wood change based on their use and look.

Common Types of Faux Wood Materials

Some common faux wood materials are:

- Hardboard: a dense, flat panel made from compressed wood fibers

- Particleboard: a panel made from wood particles that are glued together

- Laminated veneer lumber: a type of engineered wood made from layers of wood veneer

These are used to make many faux wood products, including furniture, flooring, wall paneling, and more.

The Manufacturing Process Behind Faux Wood Products

Faux wood products are made in several steps. The first part of the manufacturing process involves raw materials like PVC or polyethylene.

These materials are mixed with wood fibers or pigments. This mix looks and feels like real wood. Oridow, a top maker of faux wood, uses a special method to ensure their products last long.

The process also uses techniques like extrusion or molding, which shape the material into the right form. The final product gets finishes or coatings to look better and last longer outside.

Knowing how faux wood is made demonstrates the hard work and skill involved in making these products, which are both useful and good for the planet.

Some important steps in making faux wood include:

- Material selection and preparation

- Blending and mixing of materials

- Shaping and forming the product

- Finishing and coating the product

Faux Wood vs. Real Wood: A Detailed Comparison

| Feature | Real Wood | Faux Wood (Composite / PVC / Vinyl-wood look) |

|---|---|---|

| Material Composition | Genuine timber (hardwood or softwood) with natural grain, often stained/painted. | Engineered materials (vinyl, PVC, foam-wood composite) designed to mimic wood look. |

| Typical Lifespan / Duration | With good maintenance, ~20-60 years for windows made of wood. (American Window Company) For some premium treatments (e.g., acetylated wood) up to ~60 years. | For blinds/window treatment faux wood: often 5-10 years average. For composite windows, some sources say 40-65 years. |

| Durability / Exposure to Moisture | Vulnerable to moisture, rot, insect damage, warping if not maintained. | Very good moisture resistance; less prone to warping/cracking in humid or wet areas. |

| Maintenance Needs | Higher: periodic refinishing/sealing/painting, monitoring for rot or decay. | Lower: wipe-clean surfaces, less frequent maintenance, minimal refinishing needed. |

| Aesthetic / Customisation | Natural grain, rich textures, customizable stains/finishes — high aesthetic appeal. | Looks realistic, but some limitations in texture/variation compared to real wood. |

| Cost & Value | Generally higher upfront cost; may provide premium value for long term. | Typically lower cost; good value especially in challenging environments or for frequent replacement cycles. |

| Best Application / Use-Case | Areas where look and character matter, dry/humidity-controlled spaces, and long-term investment. | Areas exposed to moisture/humidity (bathrooms, kitchens), low‐maintenance priority settings, and budget-sensitive projects. |

| Drawbacks | If neglected, risk of warping/rotting/shortened life. Requires ongoing care. | May lack the full authenticity of natural wood grain; some may not last as long as premium wood unless high-quality composites used. |

Choosing between faux wood and real wood involves many factors. Like products from Oridow, Faux wood is durable and easy to maintain. It’s also a budget-friendly choice. Real wood, on the other hand, offers beauty and a unique look.

Faux wood stands up well to wear and tear, needing less care than real wood. It’s made from synthetic materials that fight off the elements and last longer. Plus, faux wood costs less than real wood, which is good for those watching their budget.

But real wood has its pluses, like being good for the environment. It comes from sustainable forests. Faux wood, made from synthetic materials, might have a bigger environmental footprint. So, choosing faux and real wood depends on what matters most to you.

Durability and Maintenance Differences

- Faux wood is more resistant to wear and tear

- Real wood requires more maintenance

- Faux wood is less expensive than real wood

Cost Considerations and Value

Faux wood is cheaper than real wood, making it a cost-effective choice. However, real wood can boost a property’s value, making it a smart investment for those looking to increase their property’s worth.

Popular Applications and Uses of Faux Wood

Faux wood is used in many ways, from inside homes to outside buildings. It’s durable and easy to care for. Companies like Oridow make high-quality faux wood products, like blinds and beams.

Faux wood looks and feels like real wood but lasts longer. It’s perfect for blinds, adding warmth and style to rooms. These blinds are made from PVC and polyurethane, lasting long and not fading easily.

Outside, faux wood beams are great because they handle bad weather well and need little upkeep. They’re used for design and structure outside. They also work well for furniture and decorations, like ceiling panels and wall cladding, adding warmth and class.

Key Applications of Faux Wood

- Interior design applications, including faux wood blinds and wall panels

- Exterior building materials, such as faux wood beams and decorative accents

- Furniture and decorative elements, including ceiling panels and wall cladding

Faux wood has many benefits, making it a top choice for projects. It’s durable, easy to care for, and versatile, which is why it’s so popular in the industry.

Conclusion: Making the Right Choice for Your Needs

Faux wood is a great choice for many uses, including home decor and building materials. It makes your home look better and is easy to maintain. Plus, it’s good for the environment.

Oridow is a top choice for faux wood products. They focus on quality and style. Check out their wide range to find what you need for your home or project.

FAQ

What exactly is faux wood?

Faux wood, also known as artificial or engineered wood, looks like real wood but isn’t. It’s made from wood scraps, synthetic materials, and glue, which creates a strong, wood-like material.

What are the common types of faux wood materials?

Common faux wood types include hardboard, particleboard, and laminated veneer lumber (LVL). These are made to look and act like real wood but are cheaper and last longer.

What are the key characteristics of faux wood?

Faux wood is tough, doesn’t get damaged by water or pests, and is easy to keep clean. It’s also cheaper and better for the planet than real wood, making it a great choice for many uses.

How is faux wood made?

Making faux wood involves pressing wood scraps together with glue and synthetic materials. This makes a strong, uniform material that looks like real wood.

How does faux wood compare to real wood in terms of durability and maintenance?

Faux wood is more durable and easier to care for than real wood. It doesn’t get damaged by water like real wood does. Products from Oridow are simple to clean, making them a smart choice for many projects.

What are the cost considerations when choosing faux wood over real wood?

Faux wood is cheaper than real wood, which is good for big projects or places where you need something that lasts. Making faux wood is more efficient and uses fewer resources, keeping costs down without losing quality.

How does the environmental impact of faux wood compare to real wood?

Faux wood is often better for the environment than real wood. It’s made from recycled materials and has less impact on the planet. Companies like Oridow focus on making eco-friendly faux wood products.

How do the aesthetic qualities of faux wood compare to real wood?

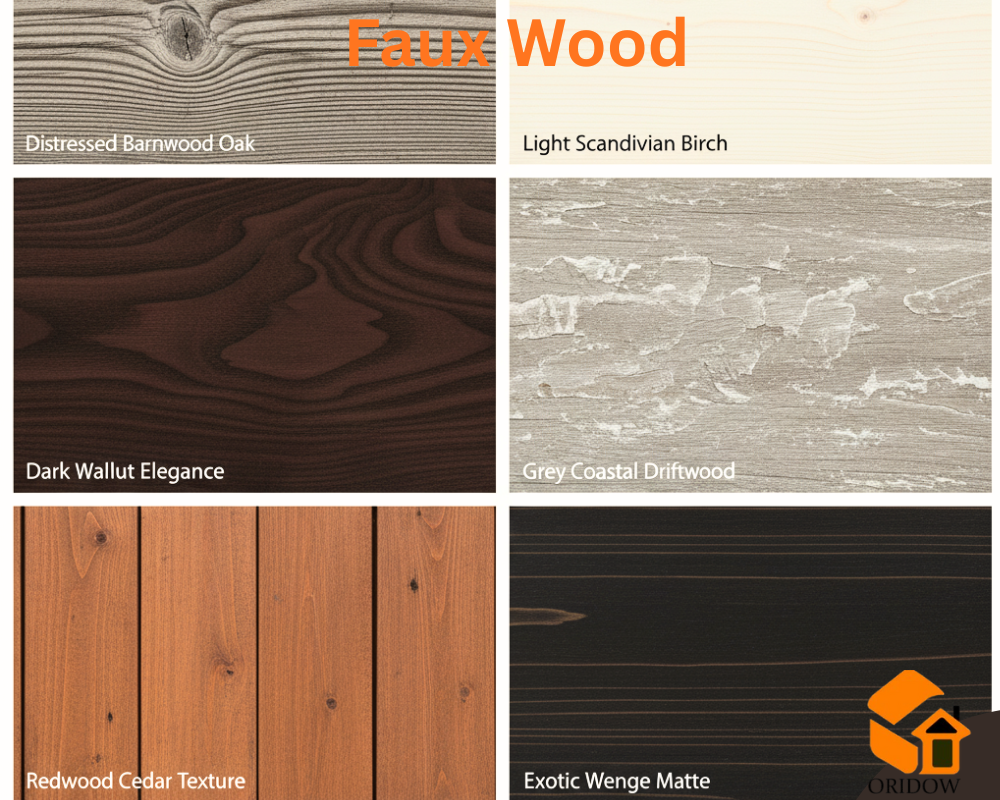

Faux wood has gotten better at looking like real wood. Products from Oridow, for example, have a natural look and feel. They offer the beauty of real wood but are more durable and easier to care for.

What are some popular applications for faux wood?

Faux wood is used in many ways, like interior design (e.g., blinds, panels, furniture) and exterior building materials (e.g., siding, beams, decking). It’s also used for decorative elements (e.g., beams, accents). Oridow offers high-quality faux wood for these uses, helping to improve spaces.