Aluminum bifold doors often look impressive in showrooms, but many fail under real-world conditions. Homeowners frequently face sticking panels, poor sealing, and frame movement within a few years, even after a significant investment. The most common cause is not installation or usage but choosing the wrong manufacturer at the start.

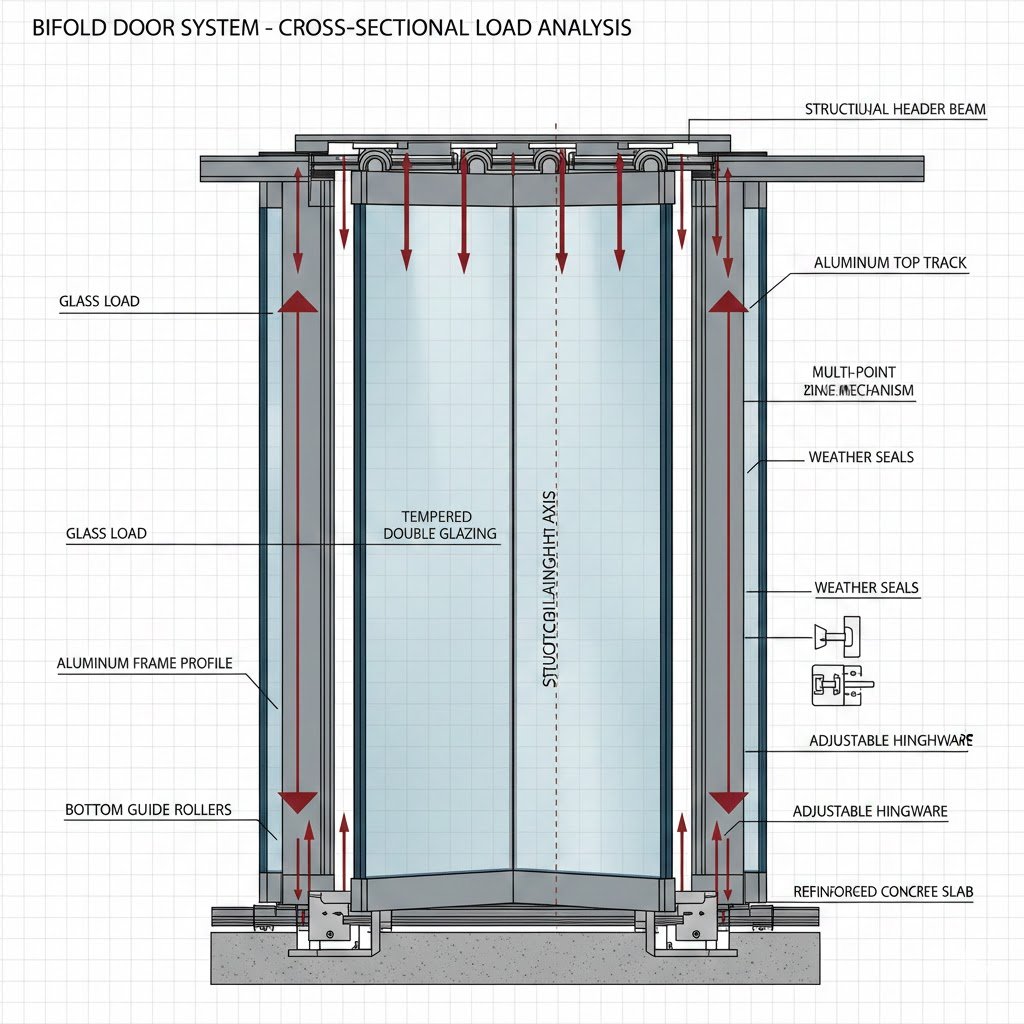

The reality is that aluminum bifold doors are complex structural systems, not decorative features. Their performance depends on engineering decisions such as profile strength, load handling, sealing design, and thermal construction. When these elements are poorly designed or inconsistently manufactured, long-term reliability suffers. Understanding how to evaluate a manufacturer allows you to avoid these risks and select a system built to perform for decades.

What Is a Reliable Aluminum Bifold Door Manufacturer?

A reliable aluminum bifold door manufacturer is one that designs complete door systems rather than assembling off-the-shelf components. Reliability means the frames, rollers, tracks, glazing, and seals are engineered to work together as a single structure.

In practical terms, a dependable manufacturer delivers:

- Structurally reinforced aluminum profiles that resist deflection

- High-load roller and track systems for large, heavy panels

- Precision sealing and drainage to manage wind and water

- Proven thermal and acoustic performance through proper glazing integration

This system-level approach is essential for wide-span doors commonly installed in modern residential and light-commercial buildings.

How Do You Choose a Reliable Aluminum Bifold Door Manufacturer?

1. Choose Aluminum Specialists, Not Generalists

Manufacturers who truly understand aluminum build their entire business around its strengths and limitations. These aluminum specialists invest in profile engineering, long-term durability testing, and purpose-built hardware rather than using generic solutions.

You should look for manufacturers that:

- Design aluminum profiles specifically for bifold applications

- Engineer frames to support large glass panels without sagging

- Offer multiple configurations and panel sizes

- Maintain consistent quality across their entire lineup

A good indicator of expertise is whether aluminum systems are the manufacturer’s core focus, not just one product among many.

2. Evaluate the Entire Bifold System, Not Individual Parts

One of the biggest mistakes buyers make is judging bifold doors by appearance alone. Slim frames mean little if the system behind them lacks strength.

When assessing bifold systems, focus on:

- Load transfer from glass to rollers and tracks

- Track rigidity under repeated opening cycles

- Panel alignment tolerances over time

- Structural meeting stiles and multi-point locking

Manufacturers that engineer doors as complete systems design these elements to work together, ensuring smooth and consistent operation even after years of use.

3. Demand Climate-Ready Design and Weather Resistance

Aluminum bifold doors must perform in real environments, not just showrooms. Intense sunlight in Australia, persistent wind and rain in the UK, and wide temperature swings across the USA place serious demands on door systems.

A reliable manufacturer will clearly address:

- Multi-stage gasket and seal design

- Integrated drainage paths within frames and thresholds

- Resistance to water penetration under pressure

- Finish protection against UV exposure and corrosion

Understanding a door’s tested weather performance is essential when large openings are exposed to the elements.

4. Don’t Overlook Thermal and Glazing Performance

Modern aluminum bifold doors are expected to contribute to energy efficiency, not work against it.

Look for systems that incorporate:

- Thermally broken aluminum profiles to reduce heat transfer

- Support for insulated double glazing

- Structural glazing methods that maintain frame rigidity

- Compatibility with regional energy requirements

High-quality aluminum systems balance slim sightlines with thermal performance, ensuring both aesthetics and comfort.

5. Installation Support Is Part of Manufacturing Quality

Even the best bifold doors can fail if installation is poorly managed. Reliable manufacturers provide clear technical documentation and support.

You should expect:

- Defined structural prerequisites for openings

- Tolerance specifications for level and plumb conditions

- Guidance on fixing methods and drainage detailing

Access to thorough installation guidance reflects a manufacturer’s commitment to long-term performance rather than short-term sales.

Comparing Aluminum Bifold Door Manufacturers

Choosing between manufacturers becomes much easier when you compare what actually impacts performance over time.

Comparison Box: What Really Separates Manufacturers

| Evaluation Area | Generic Supplier | Engineered Aluminum Manufacturer |

| Frame strength | Thin, cosmetic profiles | Reinforced profiles designed for load |

| Panel capacity | Limited sizes | Large panels with heavy-duty support |

| System testing | Minimal or undocumented | Tested for wind, water, and operation |

| Weather protection | Basic seals | Multi-stage sealing and drainage |

| Thermal design | Standard aluminum | Thermally broken, insulated systems |

| Documentation | Sales-focused | Technical drawings and specifications |

This comparison highlights why long-term reliability is tied to engineering depth rather than upfront cost.

Why Oridow Is the Right Supplier for Aluminum Bifold Doors

Oridow follows a system-driven manufacturing approach, focusing on performance, durability, and long-term reliability rather than surface design alone.

Key strengths of Oridow aluminum bifold doors:

- Reinforced aluminum profiles that maintain stability and alignment with large glazed panels

- Precision track and roller systems engineered for smooth, consistent operation

- Thermal-break construction supporting energy efficiency and comfort

- Multi-layer sealing and drainage designed for demanding weather conditions

- Durable powder-coated finishes suited for high-UV and coastal environments

By engineering each bifold door as a complete system, Oridow delivers reliable solutions for residential and light-commercial projects that prioritize structural integrity, weather performance, and everyday usability.

FAQs

How long should aluminum bifold doors last?

High-quality aluminum bifold doors typically last 25 to 40 years when manufactured with reinforced profiles, durable finishes, and properly engineered hardware.

Are aluminum bifold doors suitable for coastal or high-wind areas?

Yes, provided the system includes corrosion-resistant materials, protected finishes, and sealing designed to manage wind-driven rain.

Why do prices vary so widely between aluminum bifold doors?

Lower-priced doors often reduce costs through thinner aluminum, basic hardware, and limited testing, which can lead to early performance issues.

Can aluminum bifold doors meet energy efficiency requirements?

Modern thermally broken aluminum systems with insulated glazing can meet demanding energy standards across Australia, the UK, and the USA.

How can I verify that a manufacturer is reliable?

Review technical documentation, ask about system testing, confirm warranty coverage, and ensure the manufacturer provides clear installation and after-sales support.