Aluminum bifold doors are no longer a niche architectural feature. Across Australia, the UK, and the USA, they have become a core requirement in residential and light-commercial construction. Homeowners want wider openings, better daylight, and seamless indoor-outdoor flow, while builders want systems that are durable, compliant, and easy to install.

For wholesalers and distributors, this shift represents more than a trend. It is a scalable product category with strong margins, repeat demand, and cross-selling potential. Let’s look at why aluminum bifold doors consistently outperform many traditional door systems in the supply chain.

What Makes Aluminum Bifold Doors a High-Margin Product?

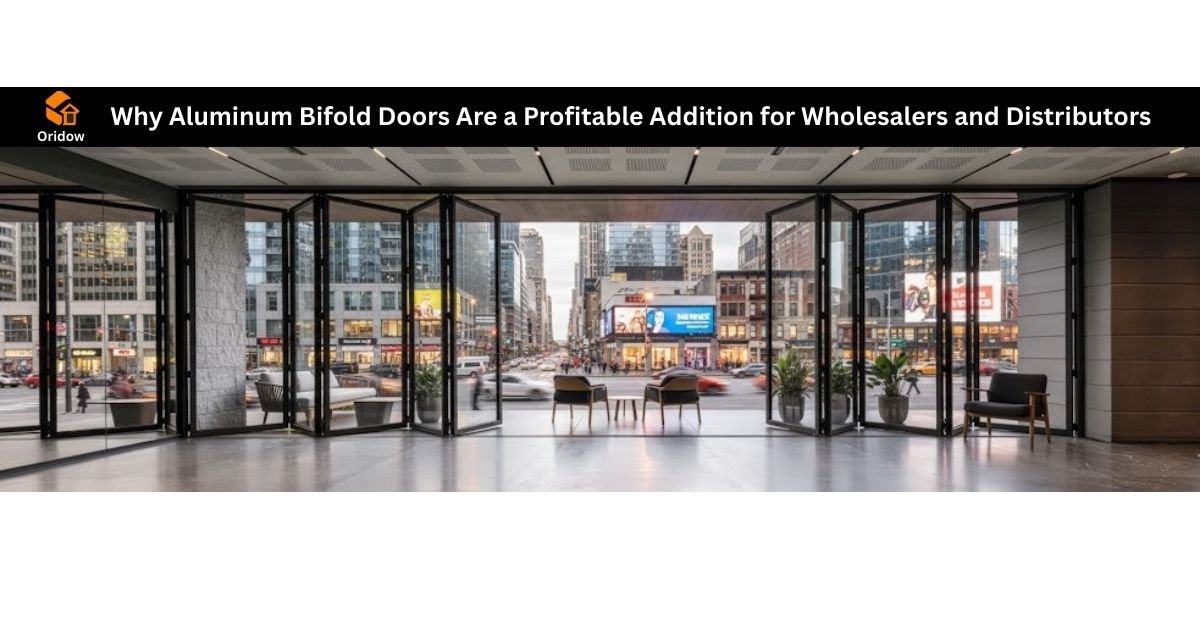

Aluminum bifold doors are multi-panel door systems that fold and stack neatly to one side, creating wide, unobstructed openings while maintaining structural strength and weather performance.

From a profitability standpoint, their value comes from a rare combination of premium pricing and broad application.

You benefit because aluminum bifold doors:

- Command higher price points than standard sliding or hinged doors

- Appeal to both residential and commercial buyers

- Offer customization options that increase average order value

- Have long service life with low warranty risk

According to construction market data across the UK and Australia, aluminum-framed openings are now specified in over 60 percent of new builds that include large patio or exterior transitions. That demand translates directly into consistent sell-through for stocked distributors.

Why Contractors and Builders Prefer Aluminum Bifold Door Systems

When contractors prefer a system, distributors sell faster. Aluminum bifold doors are increasingly selected because they solve problems that installers face on-site.

From installation to long-term performance, aluminum offers clear advantages:

- High strength-to-weight ratio supports wider panels without sagging

- Thermal break technology helps meet strict energy codes

- Corrosion resistance suits coastal, humid, and extreme climates

- Precision hardware systems reduce callback risks

Many builders also value standardized profiles and accessories available through established product lines such as these bifold systems, which simplifies procurement and project planning across multiple sites.

For wholesalers, this contractor preference means fewer objections, faster project approvals, and higher reorder frequency.

How Aluminum Bifold Doors Increase Order Value Per Project

One of the most overlooked benefits for distributors is how aluminum bifold doors naturally expand project scope.

Instead of a single product sale, you often unlock bundled opportunities:

- Matching aluminum windows and sliders

- Hardware upgrades and premium finishes

- Custom glazing specifications

- Installation accessory kits

Because aluminum bifold doors are modular, customers frequently return for additional configurations once the first project is complete. This is especially common in renovation-heavy markets like the UK and coastal Australia, where extensions and patio upgrades drive repeat purchasing.

Distributors offering a consistent aluminum portfolio through a full product range typically see higher lifetime customer value.

What Makes Aluminum Bifold Doors Ideal for Global Markets

Wholesalers serving the USA, UK, and Australia need products that adapt to local codes and weather conditions without constant redesign.

Aluminum bifold doors meet this requirement exceptionally well.

They perform reliably because:

- Aluminum does not warp or expand like timber

- Powder-coated finishes withstand UV exposure

- Multi-point locking systems enhance compliance standards

- Drainage and sealing systems manage diverse weather zones

Markets with high wind loads and rain exposure especially benefit from engineered systems designed for durability and long-term sealing performance, which directly protects distributor reputation.

How Installation Simplicity Impacts Distributor Profitability

Products that are easier to install reduce the risk of project delays, returns, and technical support costs.

Aluminum bifold door systems are designed with installer efficiency in mind:

- Pre-aligned tracks reduce on-site adjustment

- Modular panels allow phased installation

- Clear installation sequences reduce labor time

Many installers rely on standardized guidelines such as these installation steps to ensure predictable outcomes, which keeps projects running smoothly and reinforces confidence in the supplier.

For you, that means fewer technical escalations and stronger relationships with contractors.

Why Durability Drives Long-Term Distributor Growth

Durability is not just a product feature. It is a business advantage.

Aluminum bifold doors deliver:

- Lower defect rates over time

- Minimal maintenance requirements

- Reduced warranty claims

This reliability builds trust with builders and developers who prioritize suppliers that protect them from post-handover issues. When combined with proven engineering such as advanced sealing and drainage systems highlighted in weather protection, durability becomes a key selling point that differentiates your offering.

Why Oridow Is the Right Supplier for Aluminum Bifold Doors

Choosing the right manufacturing partner matters as much as choosing the right product category.

Oridow aluminum bifold doors are built with distributor scalability in mind, not just end-user appeal. The systems are manufactured using high-grade aluminum profiles, precision hardware, and tested sealing solutions suited for diverse international climates.

What makes Oridow particularly strong for wholesalers:

- Consistent profile systems across multiple configurations

- Custom sizing and finish options to support premium projects

- Engineering aligned with export market standards

- Reliable supply capacity for volume orders

Distributors working with Oridow also benefit from technical clarity and streamlined communication, which reduces friction from quotation to delivery. If you are exploring long-term partnerships, starting a conversation through their contact team often helps clarify commercial and logistical alignment early.

Strategic Takeaways for Wholesalers and Distributors

Aluminum bifold doors are more than a product. They are a category that supports predictable growth and strong margins when positioned correctly.

To maximize profitability:

- Focus on contractor-friendly systems

- Stock modular configurations with customization options

- Align with suppliers who support export and volume scaling

- Use durability and compliance as key sales narratives

As demand for open-plan living and architectural glazing continues to rise, aluminum bifold doors remain one of the most future-proof investments in the building envelope category.

Frequently Asked Questions About Aluminum Bifold Doors

Are aluminum bifold doors suitable for all climates?

Yes. Aluminum bifold doors are engineered to perform in hot, cold, coastal, and high-wind environments, making them suitable for markets like Australia, the UK, and the USA.

Do aluminum bifold doors require high maintenance?

No. Aluminum frames resist corrosion, warping, and fading, requiring minimal cleaning and no repainting over their lifespan.

Why do builders prefer aluminum over uPVC or timber?

Builders prefer aluminum for its strength, slimmer profiles, long-term stability, and ability to support larger glass panels without compromising performance.

Can wholesalers customize aluminum bifold doors for projects?

Yes. Aluminum bifold doors can be customized for size, finish, glazing type, and hardware, allowing distributors to meet diverse project requirements while increasing order value.

Are aluminum bifold doors harder to install?

No. Modern systems are designed for efficient installation with pre-aligned tracks and standardized components, reducing labor time and installation risk.