The sealing strips for doors and windows are divided into three categories: glass sealing strips (rubber strips), door frame sealing strips, and wool strips.

Glass sealing strips are used for sealing between glass and the window or door frame, door frame sealing strips are used for sealing between the door panel and the sliding door frame, and wool strips are used for sealing between the frame and the panel.

In producing and installing plastic-steel windows and doors, thermal break aluminum windows and doors, and wooden doors, sealing strips are essential accessories.

Sealing Rubber Strip

1. The Role Of Door And Window Rubber Strips

Sealing rubber strips play an essential role in waterproofing, sealing, and saving energy in uPVC windows, thermal break aluminum windows and doors, and wooden windows and doors.

They can also provide sound insulation, dust-proofing, frost-proofing, and heat preservation. They must have strong tensile strength, good elasticity, and good temperature and aging resistance.

To ensure that the rubber strip is tightly attached to the profile, the cross-sectional dimensions of the rubber strip must match those of the uPVC profile.

Sealing rubber strips are generally used for casement windows, hung windows, folding windows, a sliding window, and other types of windows and doors. They are crucial in dust-proofing, insect-proofing, waterproofing, sound insulation, and sealing.

2. The Common Positions Of Door And Window Rubber Strips

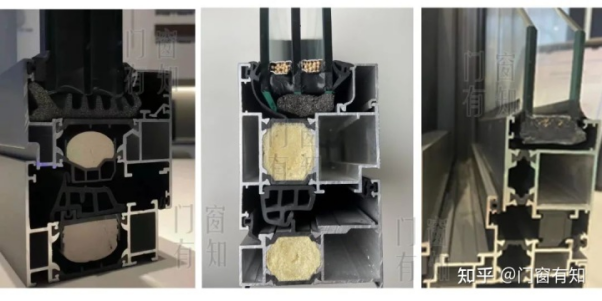

Rubber strips are commonly found in four to five positions in the structure of doors and windows:

- Two or three rubber strips are present at the position of the door or window sash, with glass gluing on both sides.

- Two or three rubber strips are present at the position of the door or window sash, but rubber strips replace the glass sealing rubber.

Some door and window structures only have a middle strip and an indoor-side strip, with no outdoor-side strip.

3. Is It Better To Use Gluing Or Sealing Rubber For The Inside And Outside Of The Glass?

Two types of connections between glass and window sashes are sealing with rubber strips and gluing.

- When the quality of the glue and rubber strip, as well as the worker’s construction level, are all at the same level, either pressure sealing or gluing can be used. The process has no absolute good or bad, and the impact and differences are limited.

- Sealing rubber is more popular mainly because

- it requires low construction technology, is neater and more beautiful than gluing, and any worker can press the rubber strip after simple training;

- it has a higher safety factor for workers, as all glass is installed indoors, and there is no need to go one side or outside for gluing;

- it is more convenient to replace the glass in the future than gluing, as the rubber strip can be removed, the pressure line can be taken down, and the glass can be easily removed and replaced;

- the outer rubber strip is pressed onto the window frame or sash before leaving the factory. The drainage holes have been pre-drilled, so there is no need to worry about water leakage due to unprocessed outer waterproofing.

- However, our country has a vast territory with significant differences between the east, west, north, and south. This seems to create some differences,

For example, in a different country where typhoons often occur, the insurance level of the adhesive process may not be sufficient, and the glass is prone to inward displacement under strong winds.

It is recommended to use adhesive on the outside to make it more reliable. In the cold northern regions, the service life of glue may not be as reliable as rubber strips.

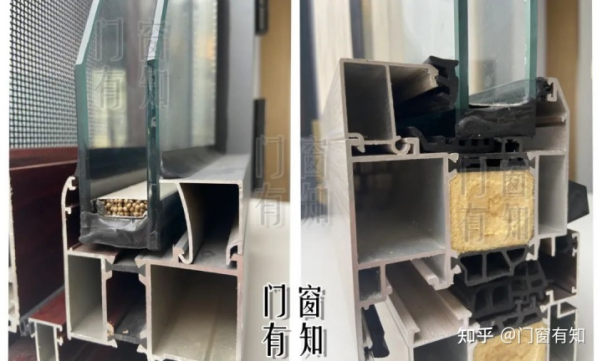

4. Does The Lack Of An Outer Frame Gasket Seal Affect The Performance?

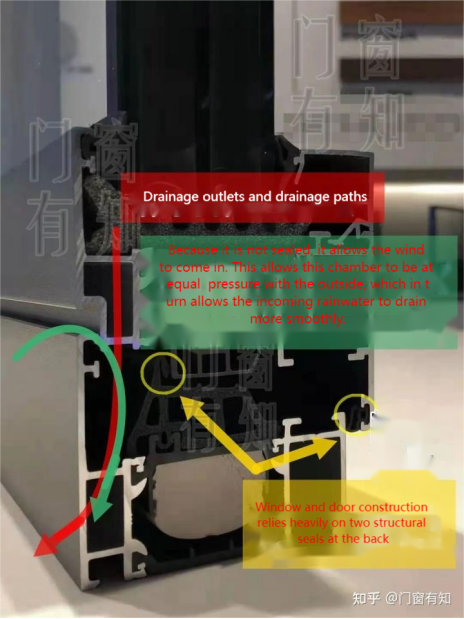

For some German brands of doors and windows, there is no gasket on the outdoor side of the window frame and the window sash. This is because it is intended to facilitate drainage.

Windows need to drain, and there will be drainage holes on the outside to allow rainwater entering the windows to flow out smoothly.

If there is an outer frame gasket, strong winds, and rain may block the drainage holes, causing rainwater to accumulate in the outer cavity.

Without an outer frame gasket, the outer cavity can communicate well with the outdoor air, and wind can help rainwater drain smoothly from the top opening.

Of course, such situations where strong winds and rain are blowing directly onto the drainage holes are not common. A closet door with outer frame gaskets can also increase the number and size of drainage holes to allow wind and water to interact.

5. Why Do We Need A Middle Gasket?

As seen from the previous paragraph, the position on the outside of the door and window structure (like a security door), regardless of whether there is an outer frame gasket, is not a complete (continuous) seal due to drainage holes.

Therefore, the sealing effect of this position is there, but it is not significant and does not play a major role (because drainage is necessary).

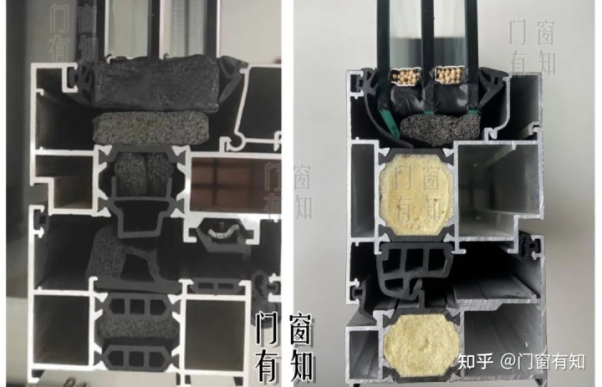

The appearance of the middle gasket, overlapping with the protruding thermal insulation strip (most common, but there is also aluminum), creates a new seal.

This seal divides the cavity between the frame and the sash into an airtight chamber and a watertight chamber, making the sealing structure of the door and window more complete and reasonable. The theoretical sealing effect of the door and window is, of course, superior.

6. Does The Shape And Material Of The Gasket Impact The Performance Of Doors And Windows?

With the development and progress of the door and window industry, gaskets’ material, type, and shape have been continuously optimized to improve the sealing performance and longevity of door and window products.

For example, designing the middle gasket to be soft and hard co-extruded is intended to increase the contact area with the insulation strip and improve operation feeling; using long-tail gaskets on the glass side can improve the insulation of the glass edge; some gaskets expand when exposed to water to improve the airtightness of the window sash position on rainy days.

7. When Selecting Doors And Windows, How Can We Judge The Gasket Quality?

Let us focus on this chapter, how to choose the ideal door and window product structure based on the gasket:

1. Choose the gasket material

Based on feedback from fans in recent times, there is not much of a problem with gasket materials.

Most merchants use popular materials such as ethylene-propylene-diene-monomer rubber (EPDM) and thermoplastic elastomer (TPE), good materials that can function for a long time.

Here are some of the advantages of EPDM rubber strips:

1)Excellent ozone and oxidation resistance: The main chain of EPDM rubber strips does not contain double bonds in its molecular structure, making it resistant to ozone attack.

In an environment with an ozone concentration of 100PPHM, it does not crack after 2430 hours. Under conditions of 50PPHM and static tensile strain of 30%, it does not crack after 150 hours.

2) Excellent weather resistance: EPDM rubber strips can be used for a long time in natural environments with sunlight, humidity, and cold. They do not crack even after being exposed to sunlight for three years, and their physical and mechanical properties change very little.

3) Excellent heat resistance: EPDM rubber strips can be used for a long time at 120°C and have a maximum operating temperature of 150°C. They begin to decompose at temperatures above 150°C.

When suitable anti-aging agents or peroxides are added, their intermittent temperature resistance can reach 315°C, a characteristic the saturated main chain structure determines.

4) Excellent low-temperature properties: The flexibility of EPDM rubber strips’ polypropylene main chain provides good low-temperature resistance.

Their glass transition temperature is between -35°C and -65°C, and most vulcanized products are still soft at -50°C, exhibiting good elasticity and less compression permanent deformation at low temperatures.

This makes them less likely to lose their sealing performance in cold regions where environmental temperatures are too low, facilitating winter construction in these areas.

5)Chemical resistance: EPDM rubber is resistant to many polar solvents, such as brake fluid, strong acids, bases, and alcohols. It is less resistant to non-polar solvents such as gasoline, but its oil resistance can be improved using ultra-high molecular weight oil-filled EPDM rubber.

6)High fill factor: EPDM rubber has a much higher filling rate than any other elastic material, making up for its high price compared to general-purpose rubber.

Using ultra-high molecular weight oil-filled EPDM rubber increases its filling rate further and has excellent tensile strength and set strength.

In addition to the above advantages, EPDM rubber also has the characteristics of low density, excellent electrical properties, high strain characteristics, strong wear resistance, high moisture resistance, and high steam resistance.

They are produced using microwave vulcanization technology in one step, with a smooth and beautiful surface, good elasticity, and resistance to compression deformation. The product has stable performance and high dimensional accuracy.

2. Choose the number of sealing strips

Under the same conditions, products with three sealing strips with a middle strip are more effective than those with two sealing strips.

If your home has high requirements and budget, choose three strips. For regular households, two strips are enough.

3. Choose the brand of sealing strips

The brand of sealing strips can be a direct factor to consider.

Common big brands of sealing strips include Jiangyin Haida, and Senpeilite, while brands with certain strengths include Lianheqiang, Ruidi, Chuangyou, Ruilongte, Yian, Gaoshida, and Aoshun.

4. Look at the shape of the sealing strip

The different shapes of sealing strips mentioned in the previous section are an extension of the function based on the material. Corresponding roles and functions still exist. If your home chooses high-demand products, you can also examine them.

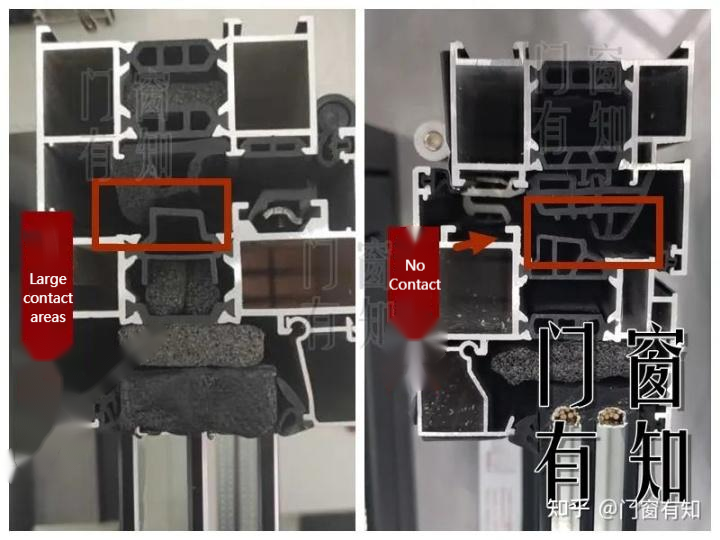

5. Look at the overlapping area of the sealing strip

Look at the contact area between the sealing strip and the frame and sash when the window is locked. Undoubtedly, the larger the overlapping area of the sealing strip, the better the sealing effect.

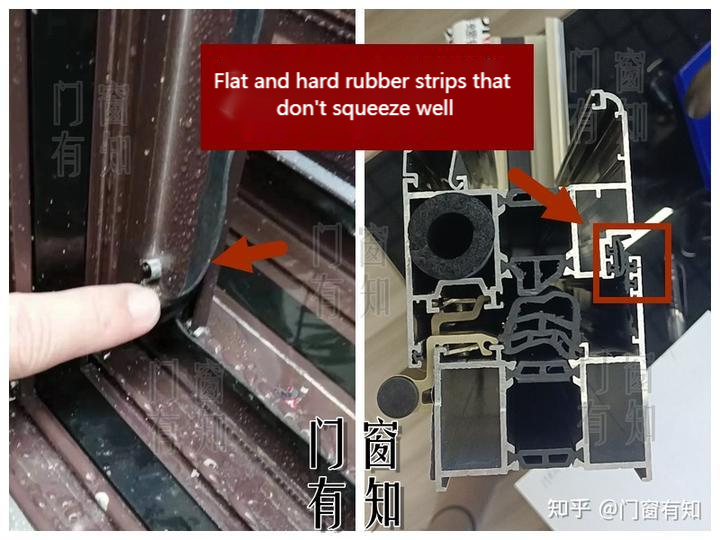

6. Feel the compression

Press the sealing strip with your hand, open and close the showroom window several times, and feel the elasticity and deformation of the sealing strip when it is pressed or opened/closed.

If you can feel the compression caused by the deformation of the sealing strip when opening and closing the window, it indicates a good sealing effect.

7 . Understand craftsmanship

The selection of sealing strips in specific parts of doors and windows, such as the corners of window frames and sashes and the hinge position, is a weak link where the sealing strips are connected.

If they are obstructed and directly disconnected, it will inevitably affect the overall sealing of the doors and windows.

A better way to deal with this is to fix the cut end with glue and use the same size of corner sealing strip, sulfur-cured integral sealing strip, or hidden hinge to improve the overall sealing of the doors and windows.