Aluminium bifold doors have come a long way in terms of thermal performance. Modern systems use thermal breaks, high-performance glazing, and advanced seals to reduce heat loss and improve year-round comfort. This means they can be far more energy efficient than many homeowners expect.

Their actual efficiency depends on the frame design, glass specification, and installation quality. U-values, low-E coatings, and gas-filled double or triple glazing all play a key role in limiting heat transfer. When properly specified, aluminium bifold doors can deliver strong insulation while maintaining a sleek, contemporary look.

Key Takeaways:

-

Thermal efficiency depends on thermal breaks, glazing performance, airtight sealing, and precise installation.

-

Lower U-values indicate better insulation; high-performance systems achieve 1.0–1.6 W/m²K.

-

Triple glazing, Low-E coatings, and gas fills significantly reduce heat transfer in cold climates.

-

Proper installation and maintained seals are essential to prevent air leakage and performance loss.

What Determines the Thermal Efficiency of Aluminium Bifold Doors?

Thermal performance depends on how well the entire system works together.

Key components include:

- Thermal break construction

- Glazing configuration

- Frame engineering

- Weather sealing

- Installation precision

Well-engineered systems showcased within the range of modern bifolding doors demonstrate how advanced profile design can dramatically improve insulation without sacrificing slim sightlines.

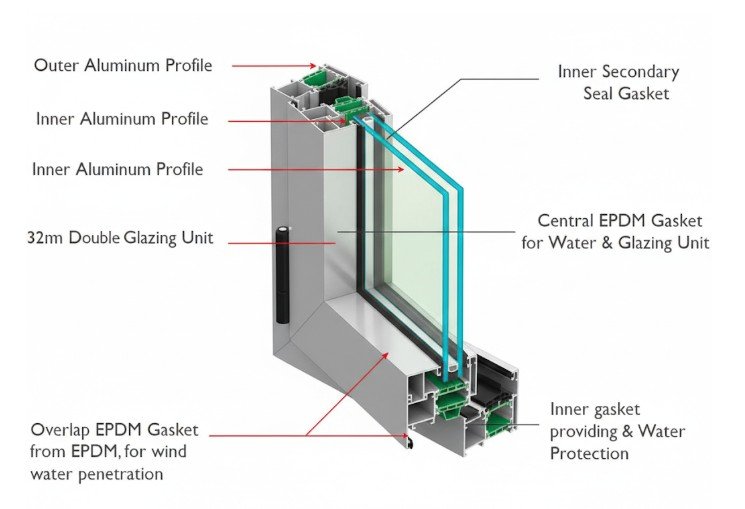

1. Thermal Break Technology: The Core of Insulation

Aluminium is a strong structural material, but it naturally conducts heat. Without insulation, it would transfer outdoor temperatures directly inside.

A thermal break solves this issue.

It is a reinforced polyamide barrier placed between internal and external aluminium sections.

Benefits of Thermal Break Systems

- Reduces thermal bridging

- Minimizes winter heat loss

- Lowers summer heat gain

- Reduces condensation formation

- Improves U-value performance

In colder climates such as the UK and northern USA, wider thermal barriers significantly enhance insulation efficiency.

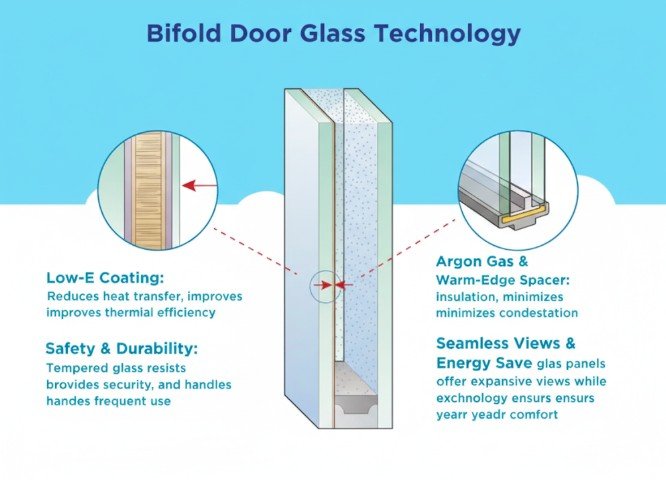

2. Glazing Performance: The Largest Energy Factor

Glass makes up most of a bifold door’s surface area. Its performance has a major impact on thermal efficiency.

Modern Glazing Options

- Double glazing

- Triple glazing

- Low-E coated glass

- Argon or krypton gas filling

- Warm-edge spacer technology

Why Glazing Matters

- Controls heat transfer

- Reduces UV penetration

- Improves acoustic insulation

- Enhances indoor comfort near large openings

If comparing specifications, reviewing detailed insulation data within a complete aluminium door collection can help you evaluate glazing compatibility and performance ratings.

3. Understanding U-Values

The U-value measures how much heat passes through a door system.

Lower numbers mean better insulation.

U-Value Comparison

| U-Value (W/m²K) | Insulation Level | Suitable Climate |

| 2.5 – 3.0 | Basic | Mild regions |

| 1.8 – 2.2 | Improved | Moderate climates |

| 1.4 – 1.6 | High-performance | UK compliance |

| 1.0 – 1.3 | Premium | Cold US zones |

Regional Benchmarks

- Australia: Typically ≤ 2.0 depending on climate zone

- UK: ≤ 1.6 under Part L regulations

- USA: 1.3–1.7, depending on Energy Star zone

Always request certified laboratory testing results for confirmation.

4. Airtight Sealing and Hardware Precision

Thermal efficiency is also about air tightness.

High-quality bifold systems incorporate:

- Multi-point locking mechanisms

- Compression weather gaskets

- Continuous perimeter seals

- Precision roller systems

Misalignment can compromise sealing performance. If adjustments are required over time, practical guidance on maintaining smoothpivot alignment and operation helps preserve long-term insulation integrity.

Are Aluminium Bifold Doors Energy Efficient in Cold Climates?

Yes, when engineered with proper thermal breaks and glazing.

Older aluminium doors lacked insulation barriers, which led to heat loss. Modern systems are designed very differently.

Ideal Specification for Cold Regions

- Triple glazing

- Low-E interior coating

- Warm-edge spacers

- Reinforced thermal breaks

- U-value below 1.4

In many scenarios, thermally broken aluminium can rival timber in insulation performance while offering superior structural stability.

Aluminium vs uPVC vs Timber: Thermal Comparison

Material choice influences both insulation and durability.

Comparative Table

| Feature | Aluminium | uPVC | Timber |

| Structural Strength | Very High | Moderate | High |

| Profile Thickness | Slim | Bulkier | Moderate |

| Insulation Method | Thermal break required | Naturally insulating | Naturally insulating |

| Maintenance | Low | Low | High |

| Coastal Resistance | Excellent | Moderate | Requires treatment |

| Lifespan | 20–30+ years | 15–25 years | 20+ with maintenance |

Why Aluminium Is Increasingly Preferred

- Supports wider openings

- Maintains slimmer sightlines

- Resists warping and expansion

- Handles extreme climates effectively

Door configuration also affects thermal performance. Understanding how panel quantity influences insulation helps you optimize performance. This guide explaining various panel layout options provides useful structural considerations.

Real-World Thermal Benefits

Laboratory ratings such as U-values and air permeability scores are important, but what truly matters is how aluminium bifold doors perform in everyday living. When properly specified with thermally broken frames and high-performance glazing, these systems create a noticeably more stable indoor environment. Instead of temperature fluctuations near large glass openings, you experience consistent comfort across the room, regardless of the season.

Reported Benefits

- More consistent indoor temperatures

- Reduced heating costs in winter

- Lower cooling demand in summer

- Decreased condensation

- Improved draft resistance

In Australia’s warmer regions, solar control glazing reduces air conditioning loads. In the UK, enhanced airtightness supports compliance with modern energy regulations.

Climate-Specific Performance Considerations

Australia

- High solar exposure

- Variable climate zones

- Wind load considerations

Recommended Features

- Low solar heat gain glass

- UV-resistant coatings

- Robust weather seals

United Kingdom

- Cold, damp winters

- Strict building standards

Recommended Features

- Triple glazing

- U-values ≤ 1.6

- Advanced compression seals

United States

- Diverse climate regions

- Energy Star certification requirements

Recommended Features

- Climate-specific glazing selection

- Certified U-value performance

- High-performance insulated profiles

How to Maximise the Thermal Efficiency of Aluminium Bifold Doors

Improving the thermal efficiency of aluminium bifold doors comes down to smart specification and careful execution. By focusing on frame insulation, glazing performance, and installation quality, you can significantly enhance energy savings, indoor comfort, and long-term performance.

1. Select Advanced Thermally Broken Frames

Choosing the right thermally broken frame is the foundation of energy efficiency. Frame design directly influences insulation performance, structural stability, and long-term durability, especially in demanding climate conditions across Australia, the UK, and the USA.

Confirm:

- Barrier width

- Reinforcement design

- Independent performance certification

2. Choose Climate-Appropriate Glazing

Selecting the correct glazing for your climate ensures optimal insulation, reduced energy loss, improved solar control, and enhanced year-round comfort in both cold and warm environmental conditions.

Ask suppliers about:

- U-value ratings

- Solar heat gain coefficient

- Gas fill type

- Spacer bar technology

3. Ensure Proper Installation

Proper installation is critical to achieving full thermal performance. Even high-specification aluminium bifold doors can underperform if sealing, alignment, and structural positioning are not executed correctly.

Installation quality affects:

- Air leakage

- Structural alignment

- Long-term thermal performance

4. Maintain Seals and Hardware

Ongoing care protects insulation performance. Simple upkeep strategies outlined in practical long-term maintenance insights help preserve both operation and energy efficiency.

Why Oridow Is the Right Supplier for Aluminium Bifold Doors

Oridow focuses on manufacturing high-performance aluminium bifold doors for residential and commercial developments worldwide. Each system is engineered in-house to address common challenges in folding door construction, including thermal insulation, structural stability, smooth panel movement, and long-term durability. Their broader architectural door portfolio reflects a commitment to adaptable sizing, advanced glazing compatibility, and climate-responsive performance standards.

What distinguishes Oridow’s systems:

- Factory-controlled production with flexible configuration options

- Thermally broken aluminium profiles designed for improved energy efficiency

- Heavy-duty roller assemblies for consistent, smooth operation

- Multi-point locking systems that enhance security and sealing performance

- Weather-resistant surface treatments suitable for varied environmental conditions

- Compatibility with double and triple-glazed insulated glass units

- Ongoing technical assistance throughout project planning and execution

Unlike generic manufacturers, Oridow’s aluminium bifold doors are developed to align with modern architectural demands and current building regulations across Australia, the UK, and the USA. For projects requiring specification clarity or configuration insight, additional technical details can be explored through their dedicated technical support platform, where performance requirements and design considerations are addressed with project-specific guidance.

FAQ

Do aluminium bifold doors lose heat easily?

Not when thermally broken and paired with high-performance glazing. Modern systems significantly reduce heat transfer compared to older aluminium designs.

Is triple glazing necessary for bifold doors?

In colder climates like the UK or northern USA, triple glazing improves insulation. In milder regions, advanced double glazing may be sufficient.

How long do thermally efficient aluminium bifold doors last?

High-quality systems typically last 20–30 years or more with minimal maintenance while maintaining both structural and thermal performance.

Are aluminium bifold doors suitable for coastal areas?

Yes. High-quality aluminium bifold doors are designed with corrosion-resistant finishes and stainless steel hardware, making them suitable for coastal environments in Australia, the UK, and parts of the USA. Powder-coated or anodised surfaces provide additional protection against salt exposure and humidity.

How secure are aluminium bifold doors?

Security depends on hardware and locking systems. High-performance bifold doors typically include:

- Multi-point locking mechanisms

- Reinforced aluminium frames

- Toughened or laminated safety glass

- Anti-lift track designs

When installed correctly, aluminium bifold doors provide strong structural resistance and secure perimeter locking.