Aluminum bifold doors are widely used in residential and commercial architecture, yet many buyers ask the same question before investing: Are they hard to open and close? With large glass panels and expansive openings, it’s reasonable to assume they might feel heavy or difficult to operate. The reality is straightforward.

High-quality aluminum bifold doors are engineered for smooth, low-effort operation and should glide easily when properly manufactured, installed, and maintained. Modern systems are built with load-rated rollers, reinforced aluminum frames, and precision-aligned tracks that distribute weight evenly across the opening. You are not lifting the panels. You are guiding a balanced system designed for controlled movement.

Across Australia, the UK, and the USA, bifold doors have become a standard feature in contemporary homes, extensions, and commercial projects. Effortless operation is no longer considered a luxury. It is a core performance requirement driven by engineering standards and evolving building expectations.

What Determines How Easy Aluminum Bifold Doors Are to Operate?

The ease of operation depends on multiple structural components working together. When engineered correctly, the doors glide with minimal resistance.

1. Roller and Track Engineering

The rolling mechanism carries the weight of the glass panels. You are guiding the door rather than lifting it.

High-performance systems typically include:

- Stainless steel or reinforced nylon rollers

- Bottom-rolling load-bearing design

- Precision-aligned aluminum tracks

- Corrosion-resistant hardware

- Even panel weight distribution

Lower-grade systems often use undersized rollers or poorly aligned tracks. That’s when friction increases and operation feels heavy.If you examine the engineering behind modern sliding Bifolding systems, you’ll notice that roller capacity and track alignment are central to smooth performance.

2. Frame Strength and Material Stability

Aluminum offers a unique balance of:

- Lightweight structural integrity

- High tensile strength

- Resistance to warping

- Minimal expansion in changing temperatures

- Strong corrosion resistance

Compared to timber, aluminum does not swell in damp UK weather. Compared to uPVC, it holds shape better under structural load in hotter US climates.The material advantages outlined in this breakdown of why aluminum outperforms alternatives explain why it remains the dominant choice in large-span openings.

Comparative Table: Smooth Operation vs. Stiff Operation

| Factor | High-Quality Aluminum System | Lower-Grade Alternative |

| Roller System | Heavy-duty, load-rated | Basic or undersized |

| Track Design | Reinforced bottom rolling | Thin or poorly aligned |

| Frame Stability | Precision extruded aluminum | Flexible or inconsistent |

| Glass Support | Balanced weight distribution | Uneven load stress |

| Operation Feel | Effortless glide | Dragging or resistance |

| Long-Term Performance | Stable over decades | Prone to misalignment |

Does Panel Size Make Bifold Doors Harder to Open?

It’s a common misconception that more panels automatically mean heavier movement.

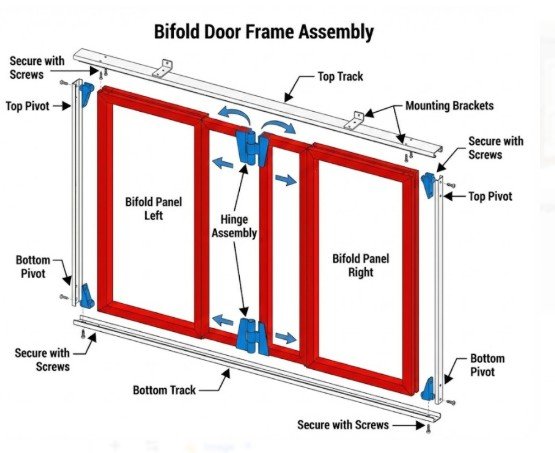

In reality, properly engineered systems distribute weight through:

- Multi-point roller assemblies

- Balanced hinge mechanisms

- Load-rated structural hardware

The number of panels affects opening width, not necessarily ease of use.If you’re planning a layout, reviewing guidance on choosing the right panel count helps balance aesthetics, usability, and structural support.

Typical Residential Configurations

- 2–3 panels for compact patio openings

- 4–5 panels for medium-width garden transitions

- 6+ panels for wide-span architectural openings

Each can operate smoothly when designed correctly.

Do Aluminum Bifold Doors Become Hard to Open Over Time?

They can, but usually only if maintenance is neglected.

Why They Stay Smooth

- Aluminum resists warping and expansion

- Frames maintain alignment

- Rollers are engineered for repeated opening cycles

- Seals help limit dirt intrusion

Why They Might Become Stiff

- Debris buildup inside tracks

- Lack of lubrication

- Worn pivot components

- Improper installation

Following structured door care practices significantly extends performance life. Most operational issues are minor and preventable.

Material Comparison: Aluminum vs. Other Door Systems

| Feature | Aluminum | Timber |

uPVC |

|

Structural Stability |

Very high | Moderate | Moderate |

| Warping Risk | Extremely low | High in humidity | Moderate |

| Smooth Glide Longevity | Excellent | Can degrade | May flex |

| Maintenance Needs | Low | High | Moderate |

| Lifespan | 20–30+ years | 10–20 years |

15–25 years |

Aluminum’s rigidity allows roller systems to function without frame distortion. That stability directly influences long-term ease of use.

The Critical Role of Installation

Even premium doors can feel stiff if installation is inaccurate.

Installation Factors That Impact Operation

- Level flooring

- Frame squareness

- Track alignment

- Structural load distribution

Improper installation may cause:

- Panel dragging

- Uneven locking pressure

- Misalignment at stacking points

If resistance develops later, replacement isn’t always necessary. In many cases, correcting amisaligned bottom pivot restores smooth movement quickly. Installation precision determines performance longevity.

How Heavy Are Aluminum Bifold Doors in Daily Use?

Glass panels are solid, but the system is engineered to minimize perceived weight.

Why They Feel Lightweight

- Bottom rolling systems carry load

- Precision bearings reduce friction

- Slim aluminum frames reduce overall mass

- Balanced hinge distribution prevents strain

Most modern systems allow multi-panel openings to glide smoothly with one hand.

High-quality bifold systems are often tested for tens of thousands of opening cycles to ensure durability without performance decline.

How to Ensure Long-Term Effortless Operation

You can significantly influence how your doors perform over decades.

1. Select High-Spec Components

Look for:

- Reinforced aluminum profiles

- Heavy-duty roller assemblies

- Multi-point locking systems

- Weather-sealed tracks

Comparing options within a broader architectural door collection helps identify structural differences before purchase.

2. Maintain Regularly

Every 3–6 months:

- Vacuum track channels

- Wipe seals clean

- Inspect roller smoothness

- Apply a suitable lubricant

Preventive maintenance avoids unnecessary strain on components.

3. Address Minor Issues Early

If you notice resistance or alignment shifts, early professional evaluation prevents long-term wear. Expert consultation and configuration support are available through the company’s project inquiry team for tailored guidance.

Market Considerations: Australia, UK, USA

Australia

- Coastal exposure requires corrosion resistance

- Large patio spans demand structural stability

- Heat management and airflow are priorities

United Kingdom

- Moisture resistance is essential

- Energy efficiency standards influence design

- Thermal break systems are important

United States

- Wider architectural openings are common

- Climate extremes require structural durability

- Hurricane or impact ratings may apply in certain states

In each region, aluminum’s structural reliability directly supports consistent operation over time.

Why Oridow Is the Right Supplier for Aluminum Bifold Doors

Oridow specialises in manufacturing high-performance aluminum bifold doors for global residential and commercial projects. Their systems are engineered in-house to address common challenges found in standard bifold designs, particularly around panel weight distribution, structural durability, and smooth long-term operation, while offering a wide range of configuration options within their broader architectural system collection.

What sets Oridow apart:

- Factory-direct engineering with flexible sizing and panel configurations

- Heavy-duty bottom rollers with load-rated performance

- Multi-point locking systems for enhanced security

- Precision corner joints and reinforced aluminum frames

- Fast global delivery supported by structured installation documentation

- Dedicated pre-sale and post-sale technical assistance

Unlike generic suppliers, Oridow’s aluminum bifold doors are developed to align with modern architectural requirements, energy efficiency expectations, and current building standards across Australia, the UK, and the USA. Structural rigidity, hardware strength, and manufacturing precision work together to deliver consistent performance at scale.

For projects requiring clarity around specifications, structural ratings, Oridow’s technical advisory team provides detailed insights to support informed decision-making and long-term reliability.

Frequently Asked Questions

Are aluminum bifold doors suitable for elderly users?

Yes. When properly installed, they require minimal effort and can typically be operated comfortably with one hand.

How often should bifold door tracks be cleaned?

Cleaning every 3–6 months is recommended. Dusty or coastal environments may require more frequent care.

What causes bifold doors to stick?

Debris buildup, worn rollers, or minor alignment shifts are the most common causes.

Do aluminum bifold doors require frequent adjustments?

High-quality systems rarely need adjustment when installed correctly. Most issues relate to maintenance rather than structural failure.

Are aluminum bifold doors durable in coastal regions?

Yes. Powder-coated aluminum frames combined with corrosion-resistant hardware perform reliably in coastal Australia, humid UK conditions, and US shoreline states.