Aluminum Windows

Factory Direct, No Middleman

Certificated Aluminum Windows

Because of the climatic characteristics of each city, different SHGC values’ glazing will be used. We provide customized glazing to meet your project. Our energy efficicnt integrated glazing units (IGU) feature double pane or triple pane glasses, warm edge spacers, argon gas fill, Low-E coating, and fully tempered or laminated glass. No matter for new construction or window replacement, they will meet your request!

how oridow makes the best energy-efficient Aluminum windows?

Step 1: use thermal Breaks aluminum Frames

A thermal break is simply piece of material positioned within aluminium frames to minimise heat loss. It separates the aluminum frame into two separate interior and exterior sections, combined with less conductive materials such as polyamide or polyurethane. Thermal break technology create an insulated barrier within the aluminum frame. This will conduct heat, cold and noise a thousand times slower than standard aluminium frame.

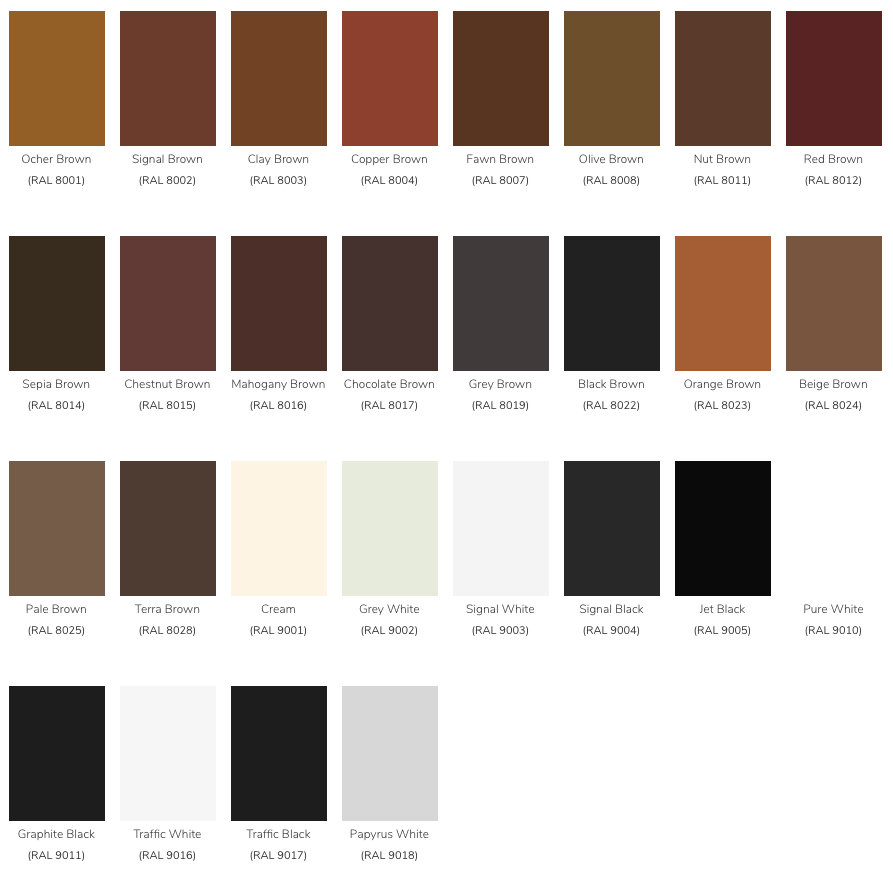

- Powder coat: The most frequently applied surface treatment for aluminium windows. During the powder coat process, a free-flowing dry powder is electrostatically applied to add color or finish effects. It is then cured via heat treatment or UV lights. The advantages of powder coating lie in the combination matrix of color, function, gloss and corrosion properties. Powder coating is the easiest way to get colorful aluminum frames. Any RAL color is available and the black aluminum windows is the popular morden aluminum windows nowsdays.

- Anodized: One of the oldest and more sustainable surface treatments of aluminium. It is a process in which the outer surface of an aluminum profile is converted into aluminium oxide, a ceramic with unique properties, which is used to create a permanent new appearance. With anodizing, the oxide layer on the surface of the aluminium is made during an electrochemical process, the natural aluminium color can be maintained, but a variety of other colors are also available.

- PVDF coating: PVDF coating is a resin-based coating with 70% fluoropolymer resins. It protects aluminium products from oxidation and provides aesthetic elements.

- Electrophoresis coating: the surface of the profile is combined with anodic oxidation and electrophoresis.

No matter which surface treatment you choose, they are available in different colors. Most of them are have white, grey and black colors at stock. We are able to customiz different colors according to the RAL color card.

Our standard aluminum profile systems available.

Window Type | Profile series | Wall thickness |

Sliding window | 85 series 2 tracks | 1.4mm |

110 series 3 tracks | 1.4mm | |

728 series 2 tracks (Non thermal) | 1.5mm, 2.0mm | |

728 series 2 tracks (Thermal break) | 1.5mm, 2.0mm | |

114 series 3 tracks (Non thermal) | 1.8mm | |

114 series 3 tracks (Thermal break) | 1.5mm | |

Casement window | K50 series | 1.4mm |

65 series (Thermal break) | 1.4mm, 1.8mm | |

85 series with integrated mosquito net (Non thermal) | 1.4mm | |

95 series with integrated mosquito net (Thermal break) | 1.4mm | |

108 series with integrated mosquito net (Thermal break) | 1.4mm | |

120 series with integrated mosquito net (Thermal break) | 1.8mm | |

135 series with integrated mosquito net (Thermal break) | 2.0mm |

Step 2: use the Energy-efficient glass

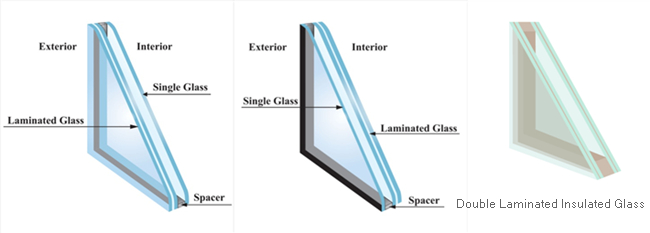

Glass is the second factor affecting the price and the most important factor affecting the U value of a complete aluminum window. There are many different types of glass. Our most commonly used glasses include Low E glass, double glazed glass, triple glazed glass, laminated glass and reflective glass.

Low E glass has been coated in invisible layers of metallic oxide. This coating allows natural light to enter the home while deflecting UV rays and infrared light back out into the environment.

Low E glass can help reduce energy costs by reducing the amount of heat that leaves and enters the home on a summer or winter day. During the summer, low E glass shuts hot air out of the home. During the winter, low E glass keeps warm air in the home to reduce the burden on the furnace.

Laminated glass is made of two pieces of regular or tempered glass sandwiched around a layer of clear plastic film (PVB). The set of glass is treated through a process intended to expel air pockets and then it is heated for an initial round of melting. After this, the glass is heated under pressure to create a finished bound product. Laminated glass can be made stronger by adding layers making the end product thicker. Even if the glass is broken, the PVB layers make the glass layers stick to them so that it does not fall out of the window frame. This glass is commonly used in impact-proof or hurricane proof windows, doors, and other applications where safety from flying debris, tropical storms, and burglars is a concern, as it is less likely to shatter than regular glass.

The standard laminated glass we use for Carribean clients are 5mm+0.76pvb+5mm, 5mm+1.14pvb+5mm. Double laminated insulated glass will also be used for more safety request.

Insulated double-glazed glass consists of two panes of glass separated by an air or gas-filled space. The panes of glass are typically separated by a gap of around 6-12mm, which is sealed to create an airtight space. The space between the panes is usually filled with air or a gas such as argon or krypton, which have low thermal conductivity and are effective at reducing heat transfer. This design helps to reduce heat loss through the window.

Triple glazed glass is similar to insulated double-glazed, but it has an additional pane of glass, which provides even more insulation. This glass is highly effective at reducing heat loss. Moreover, it is often used in conjunction with Low-E (low-emissivity) coatings or other energy-efficient features, making it a popular choice for thermal break aluminum windows in very cold climates.

Reflective glass is annealed or standard glass that has a thin layer of metallic or metallic oxide coating. Since this coating is applied to only one side of the glass, it has a mirror-like appearance.This reflective coating is applied during the float process to enhance the amount of heat reflected by the glass. It can absorb and reflect the sun’s harmful UV and infrared rays yet allow natural visible light to pass through. It also prevents excessive solar glare. However, it does allow natural light to pass through, offering optimal daylighting.

Stepe 3: use argon gas

We use the Argon Gas filled in the glazing layers in order to minimize heat transfer between the interior and exterior of the aluminum doors.

Spacers with associated sealants are used to keep the layers of glazing the correct distance apart. In addition, they provide accommodation for thermal expansion and pressure differences, while also preventing moisture and gas leaks.

We cooperates with the world’s top warm-edge spacer brand Technoform Bautec, to lower window U-factor and significantly reduce condensation at the edge of aluminum doors.

Stepe 4: use top quality hardware

Hardware plays an important role in the function of aluminium windows. Different window types need different hardware systems to meet their function. We use Kinglong brand and HOPO brand hardware, which is rust-resustant and heavy duty, and will increase the sealing resistance of the aluminum window and guarantee the energy efficiency.

Frequently Asked Questions

The cost of aluminum windows can vary depending on the size, style, and finish of the window. In general, aluminum windows are more expensive than vinyl windows but may be more cost-effective in the long run due to their durability and lower maintenance requirements.

Aluminum windows are low maintenance and do not require much upkeep. To keep them clean, simply wipe them down with a soft, damp cloth. It is important to avoid using abrasive cleaners or harsh chemicals on aluminum windows, as these can damage the finish.

Aluminum windows can be energy efficient, particularly when equipped with low-emissivity (low-E) coatings and other energy-saving features. These coatings help to reflect heat and reduce the transfer of heat and cold through the window, improving the overall insulation of the window.

Aluminum windows can last for many years with proper maintenance and care. With regular cleaning and upkeep, aluminum windows can last for 20-30 years.

Yes, aluminum windows can suffer from condensation. The excess moisture can lead to the growth of mold and mildew, which can be a health hazard. Additionally, condensation on windows can be unsightly and can obstruct your view.

There can be several reasons for the discoloration of aluminum window frames. Some of them include exposure to sun and UV rays, which can cause the aluminum to fade or become discolored. Additionally, certain chemicals and cleaning agents can also cause the discoloration of aluminum. Extruded aluminum windows are more prone to discoloration and fading.

To make old aluminum windows look new, you can try the following:

- Clean the windows thoroughly with mild detergent and water to remove dirt and grime.

- Use a metal polisher to remove any oxidation or discoloration from the surface of the aluminum.

- Protect the aluminum from further damage by applying a coat of clear sealant or automotive wax.

- If the window frame is severely damaged or discolored, you may need to have it professionally refinished or replaced.

- Regularly cleaning and maintaining your windows can help keep them looking new for longer.

To protect aluminum window frames from fading, oxidation, and corrosion, you have to properly clean the windows. In addition to that, applying a clear sealant or automotive wax on the surface is a good solution as it acts as a barrier against elements and helps prevent fading and corrosion.

An Ultimate guide of aluminum windows (2023)

If you’re in the business of selling aluminum windows, you know that these versatile and durable products are a popular choice for both residential and commercial construction projects. But with so many different types of aluminum profiles, colors, and window styles to choose from, it can be tough to keep up with all the options available. That’s why we’ve put together this ultimate guide to aluminum windows.

Whether you’re a retailer, wholesaler, or construction contractor, this resource is designed to help you understand the different types of aluminum windows on the market, how to distinguish between thermal and non-thermal options, and how to choose a quality product that will meet the needs of your customers.

So let’s dive in and explore the world of aluminum windows!”

Table of Contents

What are aluminum windows, and what makes them different from other windows?

Aluminum windows are windows that are made from aluminum frames. They are a popular choice for both residential and commercial buildings because they are durable, low maintenance, and energy efficient. You can easily spot them in any modern architectural design and buildings.

In residential buildings, aluminum windows are often used as a cost-effective alternative to wood windows. They are also popular in areas with extreme climates because they can withstand extreme heat and are resistant to corrosion.

While, in commercial buildings, these windows are often used because they are low maintenance and energy efficient. They are often used in schools, offices, hospitals, and other types of commercial buildings, as they can withstand the wear and tear of daily use by students, customers, employees, and visitors.

Differences between aluminum windows, vinyl windows and other windows

One key difference between aluminum windows and other types of windows is the material used for the frame. Wood windows are made with wood frames, vinyl windows are made with vinyl window frames and fiberglass windows are made with fiberglass frames. Each material has its own unique set of properties and characteristics, which can affect the performance, durability, and appearance of the window.

Other differences between aluminum windows and other types of windows include

Strength and durability: Aluminum is a strong and lightweight metal, making it more durable than some other materials, such as wood. Aluminum windows can withstand extreme temperatures and are resistant to corrosion, making them a good choice for use in various climates.

Maintenance: Aluminum windows are generally low maintenance and do not require painting or staining as wood windows do. Wood windows need to be repainted or restrained periodically to protect them from the elements and maintain their appearance.

Cost: Aluminum windows are generally more affordable than wood windows, but they can be more expensive than vinyl or fiberglass windows.

Energy efficiency: Both aluminum and wood windows can be energy efficient, depending on how they have been constructed and the type of glazing used. The thermal break technology is used in aluminum windows which makes them more energy efficient.

What are the types of aluminum frames used in aluminum windows?

Aluminum frames are an important component of aluminum windows as they provide structure and support for the window. They are used to create the frame and sash of the aluminum windows and hold the glass in place. There are two main types of aluminum window frames used in windows: thermal break and non-thermal break.

Thermal break aluminum window frames are designed to reduce heat transfer between the interior and exterior of the aluminum window. They are made by inserting a plastic or composite material into the aluminum window frame, which acts as an insulator. These profiles are more energy efficient and can help reduce heating and cooling costs.

Non-thermal break aluminum window frames, on the other hand, do not have any insulating material. These profiles are typically less expensive and are used in applications where energy consumption is not a concern.

What are thermal break aluminum windows?

Thermal break aluminum windows are windows that are made of aluminum, but they have thermal breaks in them. In simple words, an aluminum window that is designed in view of the thermal break technology is called a thermal break aluminum window. A thermal break is a barrier that is designed to reduce the amount of heat transfer between the interior and exterior of the window. Moreover, insulated glass is used in these windows that also acts as a barrier for heat transfer. This helps to improve the energy efficiency of the window and reduce the amount of heat loss or gain in a building.

Thermal break aluminum windows are often used in climates where there are large temperature fluctuations or where energy efficiency is a priority. They are also commonly used in commercial and industrial buildings like offices, schools, shopping malls, hospitals, retail shops as well as residential apartments.

Benefits Of Thermal Break Aluminum Windows

Thermal break aluminum windows offer a number of benefits. The following are some of them:

- Energy efficiency – One of the main benefits of thermal break aluminum windows and doors is that they are more energy efficient than traditional aluminum windows. The use of a thermal break material helps to reduce heat transfer through the window frame. Moreover, the usage of insulated glass in these windows is the cherry on top. The thermal break aluminum frames and insulated glass help to keep the interior of the building more comfortable and reduce energy costs.

- Environmentally friendly – The environment is one of the major concerns in today’s world. Major industries, manufacturers, and governments are promoting eco-friendly products. Thermal break aluminum windows are an environmentally friendly choice, as they are made from a sustainable and recyclable material and can help to reduce energy consumption and greenhouse gas emissions.

- Durability – Aluminum is a strong and durable material, and thermal break aluminum windows are designed to withstand the elements and maintain their performance over time.

- Low maintenance – These aluminum windows are easy to maintain, as they do not require painting or finishing and are resistant to corrosion.

- Improved security- Thermal break aluminum windows can be equipped with multi-point locking mechanisms and other security features to help protect against break-ins. Moreover, for the ultimate security of your building and space, you can opt to buy laminated glass aluminum windows.

- Noise reduction: Some types of thermal break aluminum windows, such as those with laminated glass, can help to reduce noise transmission from the outside, making them a good choice for buildings in noisy areas.

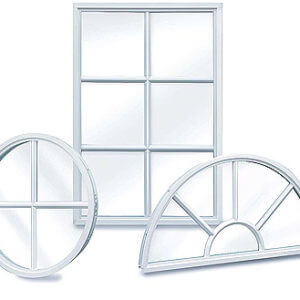

- Customization –Thermal break aluminum windows can be customized in terms of size, shape, and design to meet the specific needs and requirements of a building.

- Aesthetically pleasing – These aluminum windows are available in a range of colors and styles, making it easy to find a design that complements the appearance of the building.

Overall, thermal break aluminum windows offer a combination of energy efficiency, durability, low maintenance, customization, aesthetic appeal, and environmental friendliness, making them a popular choice for residential and commercial buildings.

What are non-thermal break aluminum windows?

Non-thermal break aluminum windows are windows that are made using aluminum frames without any insulation. These windows do not have a thermal break, which means that there is no barrier between the inside and outside of the window to reduce heat transfer. As a result, non-thermal break aluminum windows may have lower energy efficiency compared to thermal break aluminum windows. Non-thermal break aluminum windows are typically used in non-critical applications or where the cost of using thermal break aluminum frames is not justified. They may also be used in applications where the design does not require any thermal insulation.

The pros of non-thermal break aluminum windows

There are several potential advantages to using non-thermal break aluminum windows. The following are some of them:

- Cost – Non-thermal break aluminum windows are less expensive to manufacture and install compared to thermal break aluminum windows due to the simpler design and the lack of insulation material.

- Customization – Non-thermal break aluminum windows can be customized more easily compared to thermal break aluminum windows due to the simpler design and the lack of insulation material.

- Weight – These windows are lighter in weight compared to thermal break aluminum windows due to the lack of insulation material. This is an advantage in certain applications where the weight of the window is a concern.

It’s worth noting that while non-thermal break aluminum windows may have some advantages, they may also have lower energy efficiency and may not be suitable for certain applications where thermal insulation is required.

How to distinguish between non-thermal and thermal break aluminum windows?

For a layman, it’s hard to distinguish between non-thermal and thermal break aluminum windows. However, there are a few ways to distinguish between non-thermal and thermal break aluminum windows. These are as follows:

- Look for a thermal break: Non-thermal aluminum windows do not have a thermal break, so if you see a solid piece of metal running the entire length of the window frame, it is likely a non-thermal window. Thermal break aluminum windows, on the other hand, will have a visible break in the metal frame, often in the form of a plastic or rubber strip.

- Check the Energy Star rating: Thermal break aluminum windows are typically more energy efficient than non-thermal windows, so if a window has an Energy Star rating, it is likely a thermal break window.

- Look for an Energy Star label: If a window has an Energy Star label, it is likely a thermal break window.

- Check the U-value: The U-value of a window measures its ability to conduct heat. Thermal break aluminum windows typically have a lower U-value than non-thermal windows, so if you can find the U-value of a window, you can determine whether it is a thermal break window.

- Look for an R-value: The R-value of a window measures its resistance to heat flow. Thermal break aluminum windows typically have a higher R-value than non-thermal windows, so if you can find the R-value of a window, you can determine whether it is a thermal break window.

- Ask the manufacturer: If you are still unsure whether a window is a thermal break window, you can try contacting the manufacturer to ask for more information.

So these are some things that you must look for in a window in order to distinguish between thermal break and non-thermal break windows.

Colors of aluminum frames

Aluminum is a highly versatile metal that can be finished in a wide range of colors. This is important for various applications, such as architectural and industrial design, where aesthetics and durability are important considerations. There are several ways to color aluminum, including anodizing, powder coating, PVDF coating, and electrophoresis coating. Each of these methods has its own advantages and disadvantages, and the most suitable option will depend on the specific requirements of the project.

Types of Surface Treatment

The following surface treatments are popular for the coloring of aluminum window frames:

- Anodizing – Anodizing is a popular and effective method for coloring aluminum. It involves treating the surface of the metal with an electrolytic solution to create a durable, corrosion-resistant oxide layer. This layer can then be dyed in a variety of colors using organic dyes. Anodized aluminum has a glossy finish and is resistant to fading and chipping. It is also easy to clean and maintain. However, the colors available are limited to a range of shades, and it is not possible to achieve a metallic finish.

- Powder coating – Powder coating involves applying a dry powder of pigment and resin to the surface of the metal using an electrostatic charge. The powder coated aluminum is then heated to allow the powder to flow and form a continuous film. Powder coating has a smooth and durable finish that is resistant to chipping, fading, and scratching. It is also easy to clean and maintain. Powder coating is the most common type of aluminum treatment and the easiest to customize the color. Most of the black aluminum windows are powder coated.

- PVDF coating – PVDF (polyvinylidene fluoride) coating is a type of coating that is applied to the surface of aluminum profiles to improve their durability and resistance to weathering, UV radiation, and other environmental factors. PVDF coatings are made from a fluoropolymer resin that is applied as a dry powder and then cured under heat. PVDF coatings are known for their excellent resistance to fading, chalking, and peeling, and they are often used in applications where the aluminum will be exposed to harsh or corrosive environments. PVDF coatings are commonly used on aluminum profiles for windows, doors, and curtain walls, as well as on other architectural and industrial products.

- Electrophoresis coating – The electrophoresis coating process is highly efficient and is used to coat large numbers of aluminum frames quickly and consistently. It is also environmentally friendly, as the water-based solutions used in the process do not produce any harmful emissions. Another benefit of this process is that it improves the appearance of the aluminum frames by providing a smooth and glossy finish. The process involves suspending the object in a water-based solution and applying an electric current to the solution. This causes the particles in the solution to be attracted to the object, forming a thin, uniform layer on its surface.The coating is typically applied in a thin layer, ranging from 0.1 to 1 millimeter in thickness.

Each of these methods has its own advantages and disadvantages, and the most suitable option will depend on the specific requirements of the project. Anodized aluminum has a glossy finish and is resistant to fading and chipping, but the color options are limited. On the other hand, powder-coated is the most popular method for coloring of aluminum profiles as any RAL color is available in this method. Moreover, the results of this process is a smooth and durable finish that is resistant to chipping, fading, and scratching. The most popular and corden black aluminum windows is powder coating.

Colors Available

The colors available for aluminum windows frames will depend on the type of surface treatment used. Anodized aluminum window frames can be dyed in a wide range of colors, including black, blue, bronze, gold, green, grey, red, and more. The exact shade will depend on the specific dye used and the thickness of the oxide layer. Powder coat aluminum window frame is available in a wide range of colors, including metallic and matte finishes. Some popular colors include black, white, red, blue, and green. However, the exact range of colors will depend on the specific powder coating used.

Aluminum vs Vinyl, which is better?

It is difficult to say definitively which is better between aluminum and vinyl, as the most suitable option will depend on the specific requirements of the project. Here are some factors to consider when deciding between aluminum and vinyl:

- Durability: Aluminum windows tend to be strong and durable as they are resistant to weathering and corrosion. They are also able to withstand extreme temperatures and are not prone to fading or chipping. Vinyl frames, on the other hand, are softer and less durable as they tend to fade, warp, and crack in extreme temperatures.

- Maintenance: Aluminum requires less maintenance, as it does not rust or rot and is easy to clean. Vinyl, on the other hand, requires more frequent cleaning and maintenance to keep it looking new. It is also prone to staining and may require periodic sealing to prevent damage.

- Cost: Aluminum is generally more expensive than vinyl, both upfront and in terms of long-term maintenance costs. However, it is also a more durable and long-lasting material, so it may be a more cost-effective option in the long run.

- Aesthetics: Aluminum has a sleek and modern look that can complement a wide range of architectural styles. Vinyl is also available in a range of colors and styles, but it may not have the same level of visual appeal as aluminum.

- Environmental impact: Aluminum is a recyclable material, which means it has a lower environmental impact than vinyl. However, the production and transportation of aluminum can also have a negative impact on the environment.

Ultimately, the decision between aluminum and vinyl will depend on the specific needs and preferences of the project.

Mosquito screen for aluminum windows

A mosquito screen for aluminum windows is a type of mesh or netting that is designed to keep mosquitoes and other insects out of a building while allowing air to flow freely through the open windows. These screens are often made of a lightweight, durable material such as fiberglass or polyester, and are mounted on the exterior of the window frame using a variety of methods, such as Velcro, magnets, or clips.

There are several options available when it comes to mosquito screens for aluminum windows. The following are some of them.

- Retractable screen and roll-up screen for casement window, folding window, and awning window.

- Sliding screen for sliding window.

- Fixed mesh for tilt and turn window.

How to choose a quality aluminum window?

Choosing a quality aluminum window is important for wholesalers, retailers, and construction contractors as it helps to ensure that they are providing their customers with durable, energy-efficient, and aesthetically pleasing products. Poor quality aluminum window can lead to customer complaints and returns, which can impact the reputation of the wholesaler and result in lost business.

By selecting high-quality aluminum window from reputable manufacturers, wholesalers can be confident in the products they are selling and build a strong reputation for offering top-notch products. In addition, choosing quality aluminum window can help to reduce the number of repairs or replacements needed, resulting in lower long-term costs for both the wholesaler and their customers. Therefore, always prefer quality over quantity. The following are the key things that you must check in aluminum windows to determine their quality:

- Energy efficiency – Energy efficiency is one of the prime factors that you must look for in aluminum windows while choosing them. It is the key to reducing electricity or gas bills. Therefore, choose windows with double or triple glazing and low-emissivity (low-e) coatings to reduce heat loss and increase energy efficiency. For example, windows with a U-value of 0.3 or lower are more energy efficient than those with a U-value of 0.5 or higher.

- Condensation resistance – Condensation resistance refers to a window’s ability to prevent moisture from forming on the inside surface of the window. Condensation can lead to issues such as mold growth and damage to the window frame. Windows with good condensation resistance are designed to minimize this moisture build-up and reduce the potential for related issues. Therefore, choose condensation resistance aluminum windows to increase the lifespan of windows. Many windows come with condensation resistance ratings mentioned on them. Aluminum windows with a CR rating of 50 or higher are considered to have good condensation resistance.

Aluminum windows with a CR rating of 70 or higher are considered to have excellent condensation resistance and are suitable for use in more humid or extreme weather conditions. So choose such aluminum windows that have a CR rating of 50 or higher. - Durability: As you know aluminum is a durable material, however, there are many qualities available in this material. The higher the quality the more durable windows will be. You have to choose aluminum windows with reinforced corners, a multi-chamber design, a high-quality finish, and properly welded profiles. All of these things increase the strength and life of aluminum windows.

- Material thickness – The thickness of the aluminum frames is also another important factor that contributes to the quality of the aluminum window. Therefore, look for aluminum windows with thicker material, as this will provide better insulation and durability. For example, an aluminum window with a thickness of at least 1.4MM is considered to be of good quality.

- Security – Security is also another important factor that decides the quality of a window or door. Choose windows with strong locking systems and tamper-resistant hardware to increase security. So while checking the security features of any aluminum window, look for multiple locking points, and reinforced hinges to prevent forced entry. Moreover, if you are in need of extra security, you should look for aluminum windows with laminated glass.

- Manufacturer – The manufacturer is an important factor to consider when choosing high-quality windows. A reputable and reliable manufacturer is more likely to produce aluminum windows that meet high standards for durability, energy efficiency, and performance.

Here are a few things to consider when looking at the manufacturer:

- Brand reputation: Research the brand and read reviews from other customers to get a sense of their reputation and the quality of their products.

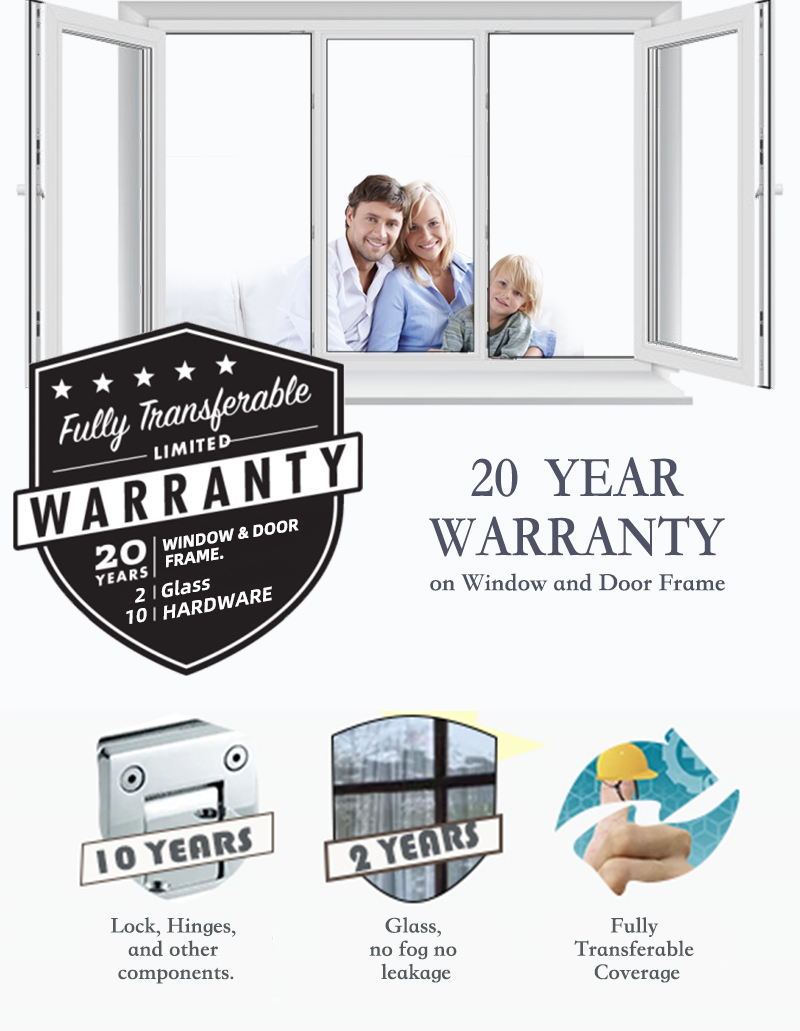

- Warranty: Choose a manufacturer that offers a long warranty period to ensure you are protected in case of any issues with the windows.

- Customer service: Look for a manufacturer that offers good customer service, including support during the installation process and after-sales support.

- Manufacturing processes: Consider the manufacturing processes used by the manufacturer to ensure the windows are produced using high-quality materials and techniques.

- Price – Last but not least, the price also matters a lot therefore, don’t forget to consider the cost of the windows. While it’s important to invest in quality windows, be sure to choose a product that fits within your budget.

get a quote

We will reply you in 24 hours after your submition!

contact us for specific configurations

Get estimation for your project

We’ll be in touch with the information you provide to select the best choice for your project. Contact us today and get an estimation for your project!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!